Brother Group Human Resources Management Policy

Published on October 1, 2025

Since its foundation, the Brother Group has consistently maintained its commitment to valuing its people.

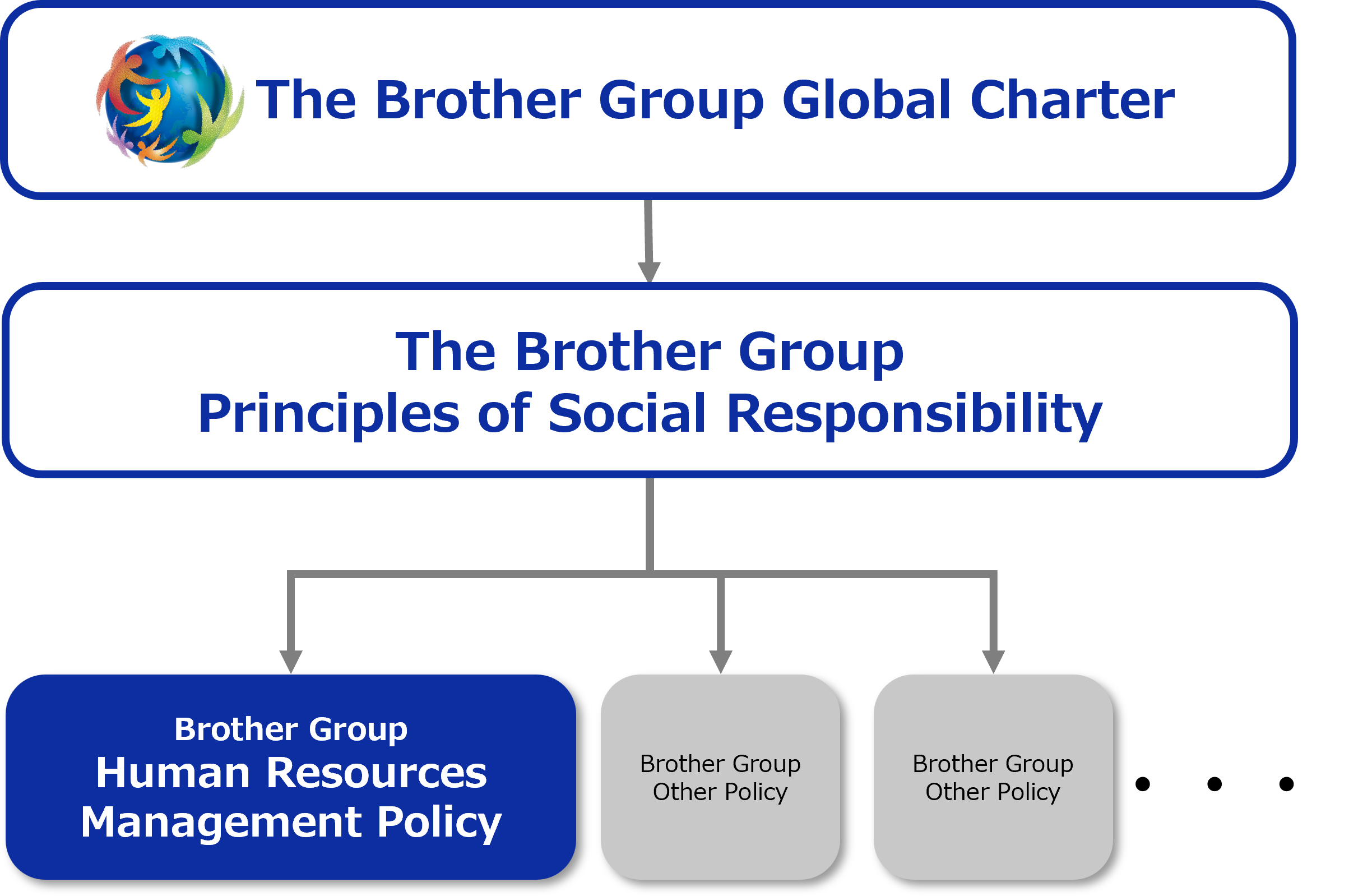

According to the "Brother Group Global Charter", we strive to create a workplace where each associate can demonstrate their abilities and thrive.

To further evolve human resources management within the Brother Group, we hereby establish the Brother Group Human Resources Management Policy (hereinafter referred to as "this Policy").

1. Scope

This Policy sets forth the guidelines for human resource management at each Brother Group company and applies to all Group locations.

2. Respect for Diversity

The Brother Group positions respect for diversity as a driving force behind its growth and innovation.

In each of human resources management processes, we place importance on DEI (Diversity, Equity, and Inclusion), strive to prevent and eliminate discrimination, and aim to bring out the strengths of both individuals and organizations.

- Diversity: We respect the diversity of backgrounds and attributes* of all people working at the Brother Group and value the diversity of opinions and perspectives that arise from these differences.

- Equity: We provide equitable opportunities by considering and accommodating each individual's background and circumstances.

- Inclusion: We foster a culture of mutual respect for differences and inclusion of diverse values, so that everyone can fully demonstrate their individuality and abilities, thereby strengthening the organization.

* Diversity of backgrounds and attributes encompasses a wide range of differences, including race, ethnicity, nationality, religion, gender, sexual orientation, age, disability status, and more.

3. Recruitment

The Brother Group seeks individuals who understand and support the direction and goals of the company and its organizations, who can contribute to the growth and innovation of the Group, and who understand and put into practice the Codes of Practice of the Global Charter.

We also strive to create employment opportunities where diverse talents can make use of their respective strengths and thrive.

4. Talent Development

The Brother Group supports each employee's independent learning and long-term demonstration of their talents and skills. To achieve this, we provide diverse learning and development opportunities tailored to individual motivation and capabilities, thereby supporting their career development.

We also continuously focus on developing leaders who will shape the future of the Group.

5. Evaluation and Reward

The Brother Group responds to employees' efforts and achievements toward goal attainment, as well as the contributions to the success of the organization and the company with fair evaluation and rewards.

We strive to design and operate evaluation and compensation systems that respond to both internal and external changes, with clear explanations to foster employee understanding.

6. Working Environment

The Brother Group complies with the laws and regulations of each country and develops a safe and secure working environment for everyone working in the Group.

We will never tolerate any form of discrimination or harassment and will work to prevent and eliminate discrimination and harassment, aiming to create a workplace where each individual is respected.

We support employees in leading healthy and fulfilling lives both physically and mentally by fostering a supportive working environment and promoting work-life balance.

7. Organizational Culture

The Brother Group places the customer first, everywhere, every time, demonstrating its motto; "At your side."

To this end, we strive to foster an organizational culture that encourages open and lively dialogue, while also creating an environment where each employee can think and act autonomously, grow, and embrace a spirit of challenge and speed.

8. Effectiveness of this Policy

Each Brother Group company shall promote human resource management based on this Policy.

To ensure its effectiveness, we will monitor the status of implementation and revise or improve measures as necessary.

Positioning of the Human Resources Management Policy

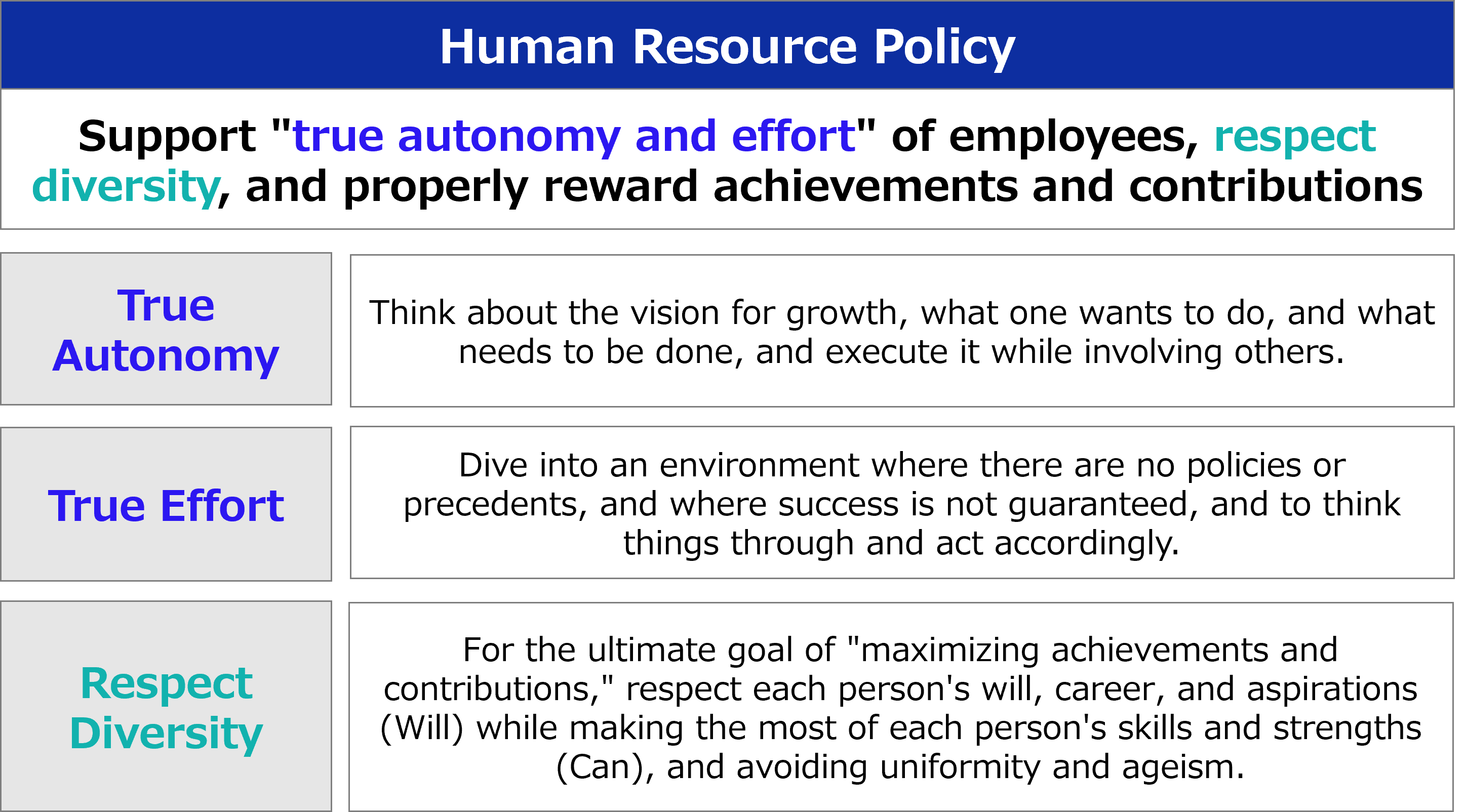

Human Resource Policy

In recent years, the environment surrounding employees and organizations has changed dramatically through not only globalization but also shifts in society's values and needs.

Under these circumstances, it is critical for the Brother Group to continue being the company chosen by customers with the spirit of "At your side." and to foster a corporate culture in which employees can work with even stronger motivation. To accomplish these goals, Brother Industries, Ltd. (BIL) formulated a "Human Resource Policy" in FY2023. Based on this Human Resource Policy, we will promote initiatives to "strengthen the talent foundation to accelerate business portfolio transformation" as set out in the Management Foundation Strategy of our Medium-Term Business Strategy "CS B2027". The Group also aims to realize the Brother Group Vision "At your side 2030" and to achieve eternal prosperity. Furthermore, the Group is implementing talent development and various other personnel measures, including a new personnel system, to enable employees to maximize their abilities.

Human Resource System

System reforms to realize the Human Resource Policy

Based on the Human Resource Policy, BIL believes that it is important for the organization and its people to work together to achieve eternal prosperity, with each of the diverse individuals constantly taking on challenges. To promote this sustainable growth, Brother Industries, Ltd. (BIL) takes a generational approach by classifying employees into four tiers from an employee lifecycle point of view.

| Tier | Approach | |

|---|---|---|

| Young | Training/early selection |

|

| Mid-level | Securing of superior human resource |

|

| Management | Pipeline strengthening |

|

| Senior | Capability strengthening |

|

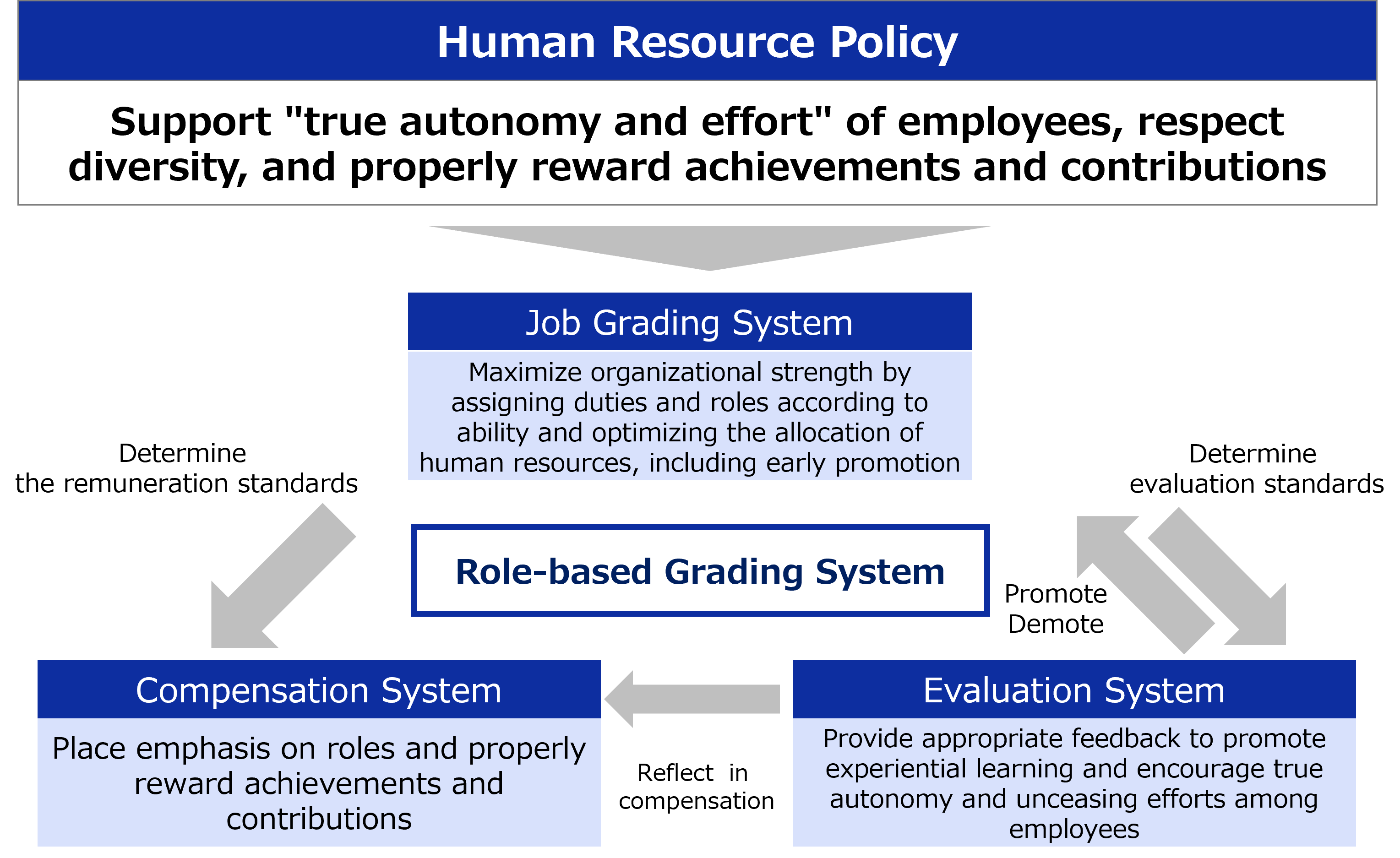

As part of this reform, we have revised our human resource system in FY2023 to encourage all employees at BIL to take on new challenges in an autonomous manner. In addition, with this new human resource system, the switch was made from the previous position-based grading system*1 that placed emphasis on experience to a role-based grading system*2 that places emphasis on the role played. In addition, in line with the change to the role-based grading system, the evaluation and compensation systems have also been revised.

- A system that places importance on experience and grades employees based on their individual abilities and capabilities

- A system that assigns grades and benefits based on the weight of the role (position) an employee assumes

Role-based Grading System and Compensation System

In April 2023, BIL transitioned from a position-based grading system to a role-based grading system and changed its compensation system accordingly. In this new system, the roles that employees play are emphasized and compensation is determined according to those roles.

Under the conventional position-based grading system, compensation increased with years of service, making it difficult to reflect the great achievements of younger employees in their compensation and requiring a certain amount of experience and period of service for promotion.

Under the newly introduced role-based grading system, grades and compensation are determined according to the role that each employee assumes, regardless of length of service, age or other factors. This will reduce the seniority-based element and enable early promotion of outstanding talents, such as fast-tracking the promotion of younger employees who are bringing about great results and contributions.

Under this system, BIL will assign roles and provide compensation according to ability so as to encourage "true autonomy and efforts," as stated in the Human Resource Policy, and "properly reward achievements and contributions," thereby maximizing organizational strength.

Evaluation System

BIL also reviewed its evaluation system in conjunction with the above transition to a role-based grading system. The new evaluation system reduces the number of rating levels in order to better differentiate each rating. Furthermore, to ensure that we place emphasis on results while also fairly recognizing what led to such results, including the willingness to take on challenges and the efforts made, we have changed the system to one that maintains the two evaluation pillars of "achievement / contribution evaluation" and "competency evaluation*" while ensuring that goal setting and evaluations are conducted in accordance with the role of the employee being evaluated.

In addition, based on the results of the Employee Engagement Surveys, BIL has reaffirmed the importance of "goal setting" as a factor to increase employee engagement. Accordingly, in addition to the introduction of the new evaluation system, BIL, since FY2023, has changed to a "goal-setting" system that can further encourage employees to take on new challenges.

In addition, BIL has created and published a new Role Definition Chart for each position and role, distributed videos and e-learning programs on the approach to goal setting and personnel evaluation, and conducted training programs for evaluators and employees in order to deepen all employees' understanding of the new evaluation system and enable them to set and evaluate goals with a common understanding.

After the evaluation is determined, feedback is provided on the evaluation results to inform employees of their strengths and challenges so that they can set their own goals for the following fiscal year. The results of the evaluation are reflected in salaries and bonuses for a highly transparent compensation system. This transparent system helps supervisors and subordinates to enhance mutual understanding and acceptance, thereby properly rewarding achievements and contributions and encouraging employees in "true autonomy and efforts."

- A method that conducts evaluation by setting evaluation criteria and items based on the common thinking and behavioral characteristics of employees who have produced excellent results.

Extension of retirement age and choice of retirement age

Once the role-based human resource system described above becomes firmly established, BIL will shift the retirement age to 65 for employees who will turn 60 years old in FY2029. This extension of the retirement age will be incrementally implemented starting in FY2026. In conjunction with the extension of the retirement age, the Brother Reemployment System will also be revised to encourage senior employees to take on new challenges and to promote their success.

By extending the retirement age and introducing a consistent employment and compensation system up to age 65, we believe we can more appropriately evaluate and reward the roles and achievements of senior employees who have experience, knowledge, and skills they have cultivated over many years.

And, in conjunction with the transition to a retirement age of 65, BIL introduced a flexible retirement age system. For more information on the flexible retirement age system and the promotion of active engagement by senior employees at BIL, please visit the following website.

Ongoing Initiatives for Diversity and Engagement

BIL is continuously working to foster diversity and enhance engagement in order to "strengthen the talent foundation to accelerate business portfolio transformation" as set out in our Medium-Term Business Strategy "CS B2027." BIL has also introduced various systems to support diverse work styles and work-life balance to achieve "Respect for Diversity," which is set forth in the Human Resource Policy.

For more information, please visit the following websites.

Details of Education System and Training (Strengthen Reskilling and Recurrent Education Measures)

BIL is actively investing in talent development in order to "strengthen the talent foundation to accelerate business portfolio transformation," as set out in our Medium-Term Business Strategy "CS B2027." Furthermore, to support the "true autonomy and efforts" stated in the Human Resource Policy, we provide growth opportunities so that employees can autonomously chart their own career paths and constantly take on challenges to establish and improve their individual expertise.

Key educational activities

BIL supports each employee to grow in his or her own way and build an autonomous career while utilizing his or her own skills and strengths. Examples include a career ownership program for employees at milestone ages to review their experiences and to visualize their future visions; extension training that accepts employees who wish to participate to learn various skills; and an overseas dispatch training program designed for young employees to gain experience overseas early on in their careers. BIL also provides e-learning options as an opportunity for self-development and subsidizes full or half tuition costs upon completion of a specified course.

In addition, BIL offers more than 20 training programs for new managers, including those on harassment, human rights, and compliance programs, in addition to management training. Besides these programs, we started one-on-one meetings between supervisors and subordinates in FY2017, to encourage the growth of employees, and the meetings are currently being conducted for 80% of the employees.

| Category | Number of Courses |

|---|---|

| Languages | Approx. 120 courses |

| Business skills/knowledge | Approx. 110 courses |

| IT/Computer skills | Approx. 30 courses |

| Qualifications | Approx. 30 courses |

| Technical skills/knowledge | Approx. 10 courses |

For details, please see the educational system diagram below.

Career development support

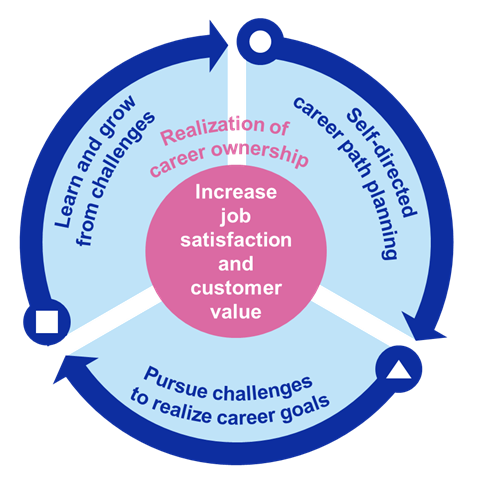

Career ownership

The Brother Group is strengthening support for employees' career development based on the concept of "career ownership." "Career ownership" refers to employees taking control of their own careers and growing autonomously. We believe that enabling self-directed career development will allow employees to face work with a more positive and energetic attitude, which will in turn lead to improved employee engagement and greater results, ultimately resulting in greater value for our customers.

In FY2024, we held a "career ownership information session" for all employees. The information session included specific explanations about "career ownership" and lectures on careers by an external lecturer and was attended by approximately 1,000 BIL employees. In addition, we are promoting initiatives to help with self-directed career development, such as publishing the "Brother Career Conversations Guidebook" on our intranet, which provides an overview of and ideas about career ownership.

Career counseling

In order to support self-directed career development, BIL has offered a career counseling system since 2022, which allows employees to meet with internal or external consultants to speak about career-related matters. During the meeting, employees can reflect on their work experience to date, consider their strengths and values, and consider their future careers from multiple perspectives. By having such meetings at milestone ages, employees are able to broaden their perspectives regarding their careers.

Investing in the development of leader talent

Terry's Challenge Academy

Since FY2014, BIL has been running "Terry*'s Challenge Academy," where the Chairman of the Board supports employees in taking on challenges. The Chairman himself serves as the instructor in this Academy, conveying to employees the perspectives and beliefs he has acquired from his more than 23 years of experience working overseas and as a leader, as well as the importance of experiencing failures and taking on challenges. Through the Chairman's lecture, participating employees will formulate a "challenge story" that clarifies what they want to achieve and the image they aspire to be. They will then refine their challenge story through multiple interviews with the Chairman and external lecturers and ultimately present their proposal to management.

A total of 238 employees have participated in the Academy since its launch in 2014 through FY2024, acquiring problem-solving approaches and strategic thinking skills. In addition, new products and services have been created based on suggestions from graduates, such as the deburring machine "Deburring Center DG-1," the spot cooler "PureDrive (This website is available only in Japanese.)," and the handwritten note-taking app "BuddyBoard (This website is available only in Japanese.)," which is team-friendly.

- "Terry" is the nickname of Chairman Toshikazu Koike, who came up with it himself while he was stationed in the United States, based on the initial "T" of his first name "Toshikazu." Brother has a culture of using honorifics (san) rather than titles, so he is referred to as "Terry-san" rather than "Chairman Koike."

External training program

BIL implements an external training program with the aim of strengthening the leadership skills of management candidates. In this program, management candidates participate in external training to learn the skills and mindset required of leaders and also interact and have discussions with employees from other companies with the aim of broadening their horizons and enhancing their perspectives. A total of 224 employees have participated in the program from 2017, its beginning, through 2024.

Female leadership development training

In FY2022, BIL launched the female leadership development training program for potential female managers.

This training program is designed to help female employees envision their unique leadership styles, identify challenges such as balancing work and family life, recognize factors that hinder their motivation and limitations they unconsciously impose on themselves, think of solutions to these challenges, and thereby broaden their career possibilities and perspectives.

From FY2022 to June 2024, the training was conducted five times, with a total of 101 female employees participating. Participant comments have included the following: "The program was very skill-enhancing and boosted my confidence" and "I gained new insights from the comments and feedback from other participants."

Training programs for new managers

In addition, BIL offers more than 20 training programs for new managers, including those on harassment, human rights, and compliance, in addition to management training.

| Purposes |

|

| Goals |

|

| Programs |

|

| Duration |

|

| Training name | Aim | Description |

|---|---|---|

| Management training |

|

|

| Harassment training |

|

|

| Compliance training |

|

|

| One-on-one subordinate development training |

|

|

| Human rights training |

|

|

| Face-to-face meeting with the president/chairman |

|

|

Brother develops talent who can tackle global business challenges

Employees develop a broad perspective and high expertise through various experiences

Since FY2008, the Brother Group has conducted the "trainee program," a training program that sends trainees from BIL to the group companies outside Japan and vice versa, aiming to foster talent who have a broad vision, high expertise, and the ability to respond to global business challenges.

This training is designed for young employees selected based on Brother's talent development plan to receive on-the-job training ranging from three months to one year in line with the training plans formulated beforehand by both their dispatchers and receivers. The initial focus of this program was to provide trainees with training associated with their area of expertise. However, in FY2015, it started offering training to help trainees gain new knowledge through experience outside their specialty. Such training, for example, includes giving an opportunity for developers to visit customers with salespersons to directly listen to the needs and usage conditions of the customers.

Also, in FY2018, the short-term external training program was started for engineers in their twenties to learn at manufacturing or repair sites outside Japan for one month. This short-term external training program has been providing an opportunity for developers to broaden their perspectives by learning about operations that differ from their usual scope of responsibilities to strengthen collaboration with overseas manufacturing facilities and by directly visiting customers to pinpoint their barriers that they face.

In FY2024, the trainee program and the overseas short-term external training program dispatched a total of 32 employees from BIL to Group companies in Germany, Taiwan, and other countries and received a total of 19 employees dispatched to BIL from Group companies in the Philippines, China, etc.

The Brother Group will remain committed to fostering globally minded talent who can deliver superior value.

Comment from an employee who used the trainee system (1)

Brother Industries, Ltd. (Japan) → Brother Industries (U.K.) Ltd. (hereinafter "BIUK")

—Automation and efficiency achieved through on-site visits—

Takahiro Ohwaki

Production Dept.

Printing & Solutions Business Division

Brother Industries, Ltd.

I was dispatched as a trainee to BIUK, a manufacturing facility in the UK. BIUK has been collecting and remanufacturing toner cartridges for printers and all-in-one devices for over 20 years since 2004, and from 2024 it has started collecting and remanufacturing ink cartridges in addition to toner cartridges. During this dispatch, I was able to identify issues with the remanufacturing line through on-site inspections and process analysis and worked to resolve them. Specifically, to further streamline and automate the remanufacturing process, we introduced to our ink cartridge remanufacturing line a robot called "COBOT*" that can work in collaboration with humans, reducing the workload by full-time equivalent per day. I also conducted a process analysis of the toner cartridge remanufacturing line, and through an actual site visit, I felt there was potential for further efficiency improvements and automation. In the future, I would like to take advantage of my experience at BIUK and take the initiative in further promoting automation.

- Abbreviation for "Collaborative Robot." Robots designed to work alongside humans.

Comment from an employee who used the trainee system (2)

Taiwan Brother Industries, Ltd. (hereinafter "BITW") → Brother Industries, Ltd. (Japan) (BIL)

—Learning about Japan's approach to and initiatives regarding quality control—

Lin, Shao Fang

Quality Management Dept.

BITW

I am in charge of product evaluation of home sewing machines and was dispatched to BIL from BITW, a manufacturing facility in Taiwan, with the aim of further improving and enhancing our evaluation work. In this training, I disassembled a sewing machine to gain a deeper understanding of its structure and learned about its structure and parts, which are important for product evaluation. In addition, I learned about all aspects of product evaluation from BIL's quality control department, which gave me an understanding of the overall quality management system. Furthermore, through on-site observations of quality control and quality assurance activities in Japan, I realized that in order to achieve a higher level of quality evaluation, it is important to create a procedure manual that clearly defines the evaluation flow and procedures, implement that manual, and make improvements as necessary. In the future, I would like to actively implement what I learned from Japanese quality control activities in this training, including creating procedure manuals, at BITW, and I aim to further improve my quality evaluation techniques.

Development related to manufacturing

Takumi Dojo

BIL's Machinery Business has been conducting a Meister program called "Takumi Dojo" since 2006 with the aim of handing down the craftsmanship of skilled workers to the next generation. In this program, young employees meet twice a week for a year to learn skills and work attitudes from experienced workers. If participants are unable to complete a task, they are asked to repeat the year and try again until they have mastered the skill, with the aim of ensuring thorough skill transfer to ensure product quality. By FY2024, more than 80 employees, including employees of Group companies, graduated from the Dojo.

Through these efforts, we are further raising the level of our manufacturing and building a system that allows us to continue to provide high-quality products in a stable manner.

Onboarding training (development for mid-career recruits)

BIL implements the Brother Onboarding Program for mid-career recruits, aiming to enable them to quickly become successful and produce results.

This training provides participants with the knowledge they need to work at BIL, as well as sessions based on the Brother Group Global Charter, which serves as the foundation for all Brother Group activities, providing an opportunity to learn about the Brother Group's values. This program also serves as an opportunity to build networks among mid-career recruits, and as part of this, it holds "follow-up training," where employees who joined the Company at the same time meet to have face-to-face discussions, and "Talks with the President," where employees can speak with the President in small groups. During "Talks with the President," the President directly speaks about his expectations for mid-career recruits and the direction the Brother Group is aiming for, providing an opportunity for participants to understand the thoughts and feelings of top management and reaffirm their own roles. Mid-career recruits also ask frank questions and offer their opinions, creating two-way communication that fosters understanding of the Company and a sense of belonging.

Development of DX Talent

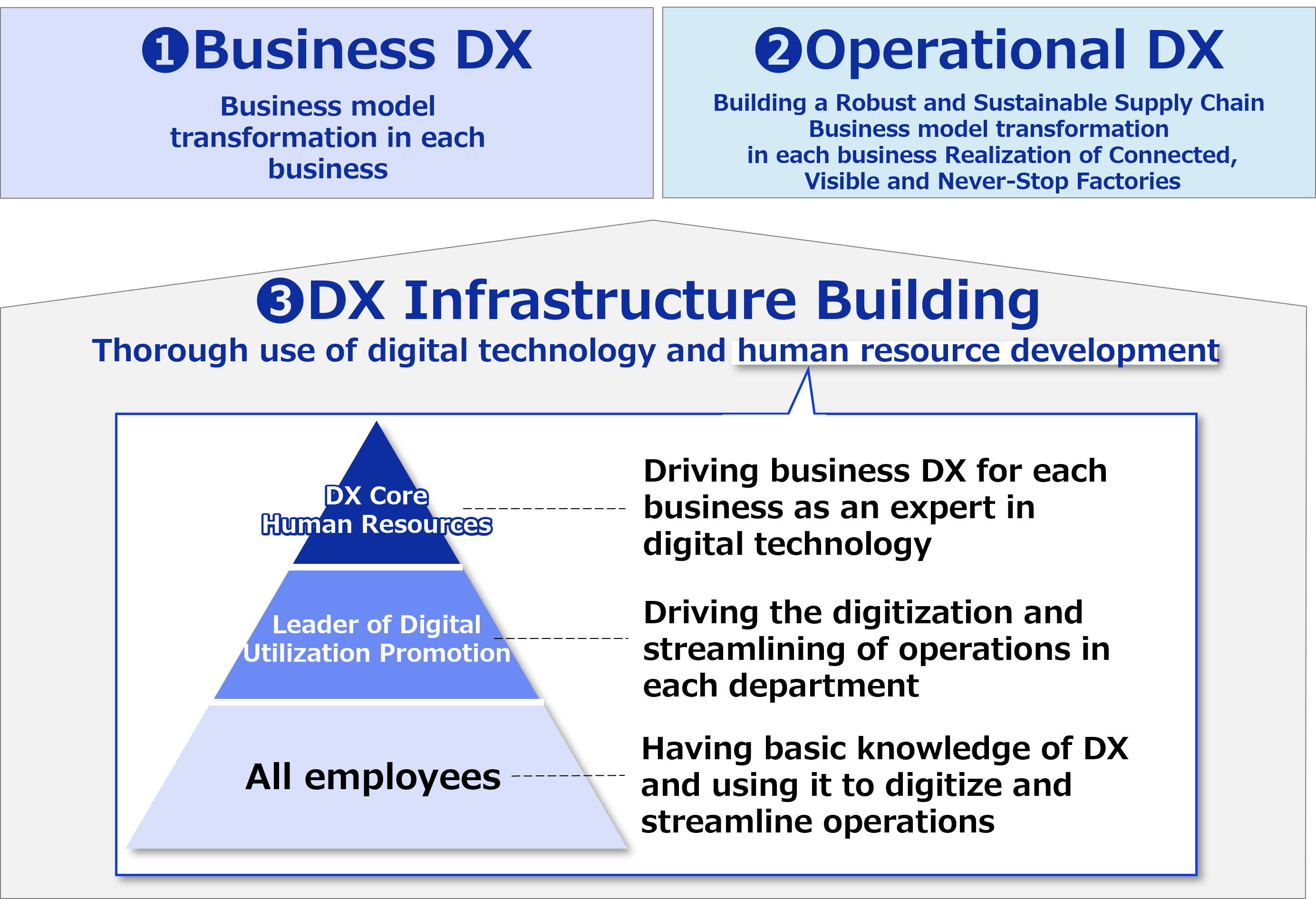

The Brother Group is developing human resources capable of DX* in order to raise the level of digital skills across the Company and develop talent who can lead business process reforms.

The Brother Group's DX strategy consists of three pillars: 1) Business DX (business model transformation in each business), 2) Operational DX (building a robust and sustainable supply chain), and 3) Building DX infrastructure (thorough use of digital technology and talent development). To build the foundation, we are promoting the continuous development of DX talents throughout the Group. The development of DX talent is divided into three levels: "Core DX talents," "Leaders of Digital Utilization Promotions," and "All employees."

- Abbreviation for digital transformation. Transformation of business and life through information technology (IT) such as high-speed Internet, cloud services, and artificial intelligence (AI).

| Description | Training record | |

|---|---|---|

| Core DX talents |

|

|

| Leaders of Digital Utilization Promotions |

|

|

| All employees |

|

|

AI utilization project to foster AI-led talents development

BIL launched operational efficiency projects in 2018. They are aimed at groupwide promotion of automation and greater efficiency in routine tasks by utilizing RPA* and artificial intelligence (AI). One such example is the AI utilization project led by a software development department under the slogan "AI Everywhere." to enable AI application voluntarily by each employee. In this project, we are conducting AI training using an original curriculum that we have created ourselves. We also share the latest AI technology and examples of in-house AI use through a dedicated intranet site. Furthermore, we are also working to support the use of AI to solve on-site problems.

The internal AI training program aims to assign at least one AI talent to each business division and, to this end, offers programming courses for beginners to encourage employee participation regardless of level of basic knowledge or affiliation as well as AI development project experiential training where participants can learn about operational precautions and points to consider when running an AI program . The program has been received very favorably among the participants, who said that, "It was a great opportunity to learn how to make use of AI, which I knew nothing about" and "Actually experiencing programming in the workshop gave me a clearer picture of what I will be doing." In fact, AI application by employees who have completed the course is growing steadily at various work sites.

Examples of AI application in manufacturing are unmanned operation and improved inspection accuracy for the shape of inkjet printer head nozzles and automation of pre-shipment inspection of industrial sewing machines. Working in cooperation with inspection personnel from each department, project members worked to clarify the issues, collect a huge amount of data needed to utilize the AI system, train the system, and conduct trial operations of the system. This enabled inspection personnel to deepen their knowledge of AI, leading to the application of AI at manufacturing sites.

- Acronym for Robotic Process Automation, referring to automation of business operations with the robots (replacement of people with robots for multiple routine application operations).

Training and education record

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|

| Total hours*1 | 104,758 hours | 104,450 hours | 166,698 hours | 118,610 hours | 116,061 hours |

| Training types | position-based education, new manager training, extension training, trainee program*2, etc. | ||||

| Average amount of money per employee | 70,746yen | 78,837yen | 106,025yen | 125,241yen | 190,761yen |

| Average number of days per employee*3 | 1.15 days | 1.13 days | 1.79 days | 1.27 days | 1.24 days |

| Average amount of time per employee | 27.55 hours | 27.01 hours | 42.85 hours | 30.59 hours | 29.74 hours |

- Covers only company-wide training programs conducted by the Human Resources Dept. and the Production Strategy Planning Dept. (OFFJT)

- The trainee programs were suspended between FY2020 and FY2021 due to the impact of the COVID-19 pandemic, but gradually resumed from FY2022.

- Includes training and education programs provided by each department in addition to training programs conducted by the Human Resources Dept. and the Production Strategy Planning Dept.