Environmental Management Framework

Globally managing environmental issues throughout the group

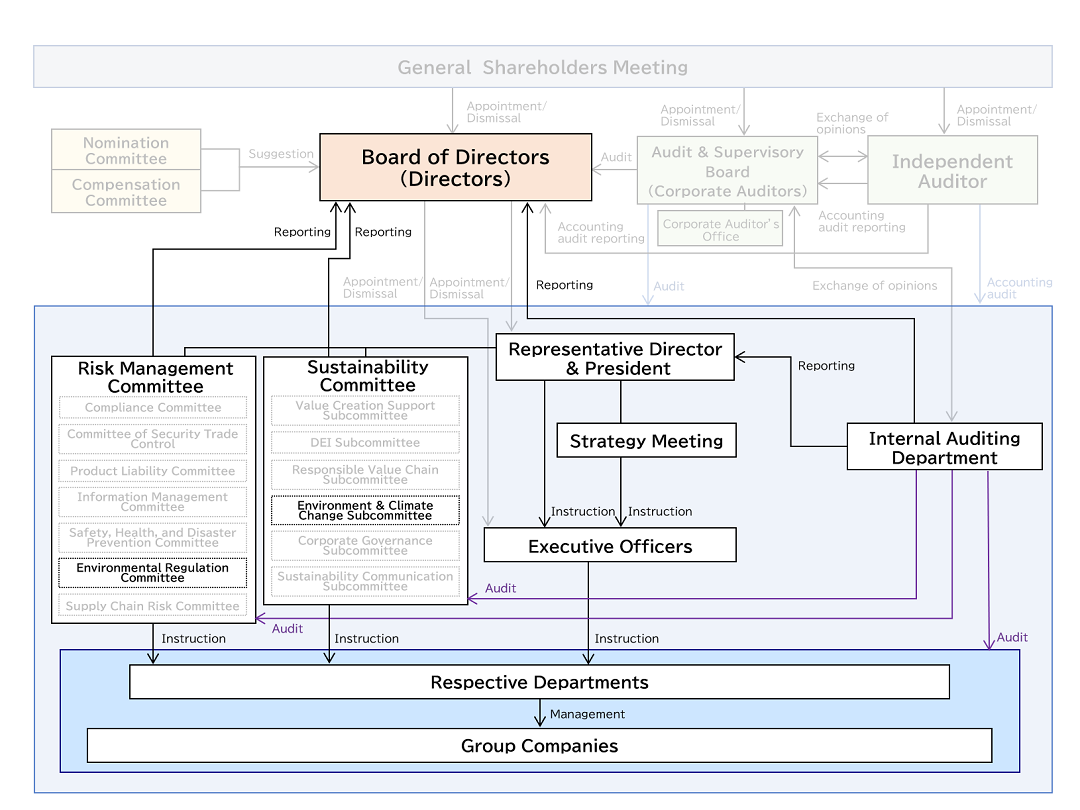

The Brother Group promotes global environmental conservation according to the Brother Group Environmental Policy. To do so, the officer in charge of environmental affairs instructs respective departments at the head office as well as divisions and function centers through the Environment & Climate Change Subcommittee (a subcommittee that promotes materiality resolution under the Sustainability Committee) and the Environmental Regulation Committee (a committee that works on environment risk reduction under the Risk Management Committee) to determine policies and implement measures.

Brother Group environmental management framework (As of June 25, 2025)

Environment & Climate Change Subcommittee

The Environment & Climate Change Subcommittee is an organization responsible for managing progress and promoting activities related to each goal of the Brother Group Environmental Vision 2050. It is chaired by the head of environmental department, and composed of the related departments and other persons concerned. Subcommittee meetings are held three times a year, and extraordinary meetings are held as necessary. Serious environmental issues raised at the Environment & Climate Change Subcommittee are reported to the Sustainability Committee chaired by the representative director & president. In addition, top priorities are reported to the Board of Directors for instructions and supervision from management. In FY2024, the subcommittee reported on CO2 emissions reduction and resource circulation targets, which are the top priorities related to climate change.

Environmental Regulation Committee

The Environmental Regulation Committee is an organization responsible for managing and addressing environmental risks such as environmental laws and regulations. It is chaired by the executive officer in charge of environmental affairs, and composed of the heads of related departments and other persons concerned. Committee meetings are held three times a year, and extraordinary meetings are held as necessary. Serious environmental risks related to environmental laws and regulations raised at the Environmental Regulation Committee are reported to the Risk Management Committee chaired by the representative director & president. In addition, top priorities are reported to the Board of Directors for instructions and supervision from the management.

No serious environmental accidents occurred in FY2024.

Environmental Communication Promotion Framework

In 2010, the Brother Group created and launched the "Brother Earth" logo and slogan, which symbolize its environmental activities, in order to convey a globally unified message about its various environmental activities.

In 2022, we formulated the Basic Policy on Sustainability. From 2025, we have expanded the scope of "Brother Earth" to include not only environmental activities but also sustainability as a whole. We are working to communicate various sustainability-related activities under the unified group message of "Working with you for a sustainable future."

The Brother Group has made "environment" its materiality and established working on activities to enhance the environmental brand image as the basic policy for environmental communication. The Corporate Communication Department takes the initiative to promote environmental activities at facilities around the world.

Brother SDGs STORY "Click for the Earth" is an environmental conservation activity that Brother conducts together with you.

Environmental Management System

Under our medium-term management plan, the Brother Group creates the Brother Group Environmental Action Plan every three to five years, based on which Brother Industries, Ltd. (BIL) and manufacturing and sales facilities in respective countries set annual plans and carry out environmental activities as part of their business operations. The progress and performance (results) of plans are checked based on reports from and internal audits on each facility, and the findings are then reflected when planning for the following year.

PDCA cycle using ISO 14001

In operating the environmental management system for environmental conservation activities, compliance with laws, regulations, and standards is ensured, and the ISO 14001-based PDCA (Plan - Do - Check - Act) cycle is practiced. The Brother Group annually conducts internal audits and is also subject to examination by external certification body.

ISO 14001 certification has been obtained by the main group manufacturing facilities, with Brother Industries (U.K.) Ltd. being the first to be certified in 1996. Brother U.K. Ltd., a sales facility in the U.K., obtained certification in 2005, followed by other many sales facilities.

Environmental training for employees

The Brother Group's ISO 14001-certified facilities offer environmental training programs for all employees as well as job specific training related to specific tasks and functions.

Examples include environmental training programs for all new recruits joining Brother; environmental training programs for employees such as e-learning-based materials, internal seminars and workshops; training programs for production and procurement staff at manufacturing facilities in and outside of Japan, for example, the management of chemical substances contained in products, process control guidance and auditing at suppliers. Essential environmental training is periodically provided to raise eco-awareness and facilitate operations.