The Brother Group is promoting CSR procurement on a global scale and strengthening its commitment toward "Pursuing a responsible value chain" as stated in the materiality.

Promoting CSR Procurement

The Brother Group makes its "Procurement Policy" and "CSR Procurement Standards" publicly available and shares its CSR procurement concept with parts and materials suppliers. The policy and standards cover a wide range of fields, including human rights and labor, the rights to organize and bargain collectively, safety and health, global environmental protection, fair trade and ethics, product quality and safety, raw materials, information security, and social contribution. The Brother Group complies with local laws and regulations and supports workers' collective bargaining rights by conducting collective negotiations and respecting communication between management and employees on working conditions and management practices.

In addition, the Brother Group is also implementing initiatives for the responsible procurement of minerals, such as conducting a mineral procurement survey and establishing a working group to confirm that mineral resources that are mined in conflict-affected and high-risk areas*, and may be involved in violation of human rights, violation of labor rights, environmental degradation, etc. are not used.

- Conflict-affected and high-risk areas: areas with a high risk of armed conflict, violence, and human rights violation

Procurement Policy/CSR Procurement Standards

Procurement policy

- The Brother Group acts fairly with all suppliers.

- The Brother Group respects the rules and spirit of laws in all countries and regions where we operate, and builds strong, respectful working relationships with suppliers for mutual growth.

- The Brother Group promotes environmentally friendly "green procurement," and reduces impact on the environment through the lifecycle of its products.

- The Brother Group places our customers first everywhere, every time, while remaining committed to delivering high quality products and services at reasonable costs.

- The Brother Group considers human rights violation, labor rights violation, environmental degradation, etc. in mining and trade of minerals as very important social issues, and will take proactive approaches toward the responsible procurement of minerals.

CSR procurement standards

The Brother Group procures products and services from business partners that adhere to the following guidelines:

Labor

- Respect for Human Rights and Prohibition of Discrimination

Respect fundamental human rights of all people, and do not discriminate by race, nationality, gender, religion or creed. Understand the Brother Group Human Rights Global Policy, establish your own company policies of the same standard, and have your employees strictly follow them. - Prohibition of Child Labor and Forced Labor

Do not enforce unfair labor practices and illegal labor of children at any production stage.

Appropriate Management of Working Conditions and Prevention of Overwork. - Appropriately manage employees' working conditions including working hours in accordance with local labor laws and regulations, and prevent overwork with consideration for employees' health such as by providing adequate rest days.

- Guarantee of Minimum Wage

Pay wages higher than the legal minimum in accordance with local labor laws and regulations, and do not reduce wages unfairly. - Guarantee of Freedom of Association and Support for Collective Bargaining Rights

Respect the rights of employees to associate freely with others and join or not join the association as a means to facilitate consultation between labor and management over working conditions, working environment, wage levels, etc. In addition, support collective bargaining rights and hold sincere consultations and discussions with employees.

Safety and Health

- Health and Safety Conscious working Environment

Ensure the safety and health of employees and act to create a comfortable working environment.

Environment

- Environmental Consciousness

Take proactive measures to protect the global environment. Comply with the Environmental Supplier Guideline.

Ethics

- Legal Compliance

Respect the rules and spirit of laws, and act fairly with the highest integrity. - Adequate Information Management

Have a framework for managing information in place, and keep personal information and confidential information secure. - Responsible Procurement of Minerals

To promote the responsible procurement of minerals, it is strongly suggested to avoid the use of minerals mined or traded in conflict-affected and high-risk areas, which may be involved in human rights violation, labor rights violation, environmental degradation, etc., as raw materials in reference to the Policy on the Responsible Procurement of Minerals.

Management System

- Provision of Superior Quality

Work on building a framework for delivering safe, high quality products and services to customers who use our products and services. - Continuous Improvement of Activities

Use CSR procurement questionnaires, surveys and any other various explanatory materials provided by us to engage in continuous, PDCA-oriented improvement efforts in fulfilling societal demands.

Contribution to Sustainable Society

- Social Contribution in Consideration of Communities and the Environment

Make efforts to become a good corporate citizen through social contribution activities while sharing our social, economic and cultural resources in communities and considering the global environment.

Request for Cooperation to Business Partners

- Request for Cooperation to Your Business Partners

Request your business partners to cooperate with our efforts to fulfill social responsibilities from the viewpoints of legal compliance, human rights, labor, safety and health, environment, ethics, management system, etc. stated in these CSR Procurement Standards (including any policies, guidelines, documents, etc. cited in the Standards and/or separately provided to you; hereinafter the same shall apply in this section) at the same level as the Standards, as well as establish any process to check the status of your business partners' initiatives at the request of the Brother Group.

Responsible Business Alliance

Since Brother Industries, Ltd. (BIL) joined the Responsible Business Alliance (RBA) in January 2019, we have been strengthening our supply chain risk assessment and the implementation system for corrective actions based on the assessment results in the areas of labor, health and safety, environment, ethics, and management systems as stated by the RBA in its Code of Conduct.

RBA Recognition Received

The Brother Group has been promoting audits of its sites by third-party organizations accredited by the RBA. As a result, since FY2022, four of its manufacturing facilities have obtained RBA certification. This achievement fulfills one of the sustainability targets set to address the Group's material issues under its previous medium-term business strategy, CS B2024 (FY2022–FY2024): "Attain RBA Gold certification for three Group manufacturing facilities." Moving forward, the Brother Group will continue working to further enhance its initiatives to build a sustainable supply chain, including improving workplace safety and minimizing environmental impact at its manufacturing facilities.

For details on facilities with RBA recognition, please view Responsible Business Alliance under Management with an Emphasis on Sustainability—Participation in External Initiatives.

Using a Self-Assessment Tool

Since FY2023, the Brother Group has conducted annual self-assessments using the self-assessment tool provided by the RBA. These assessments have been implemented at manufacturing facilities of the Printing & Solutions (P&S) Business, the Machinery Business, the Nissei Business, and the Personal & Home Business, as well as at Brother Industries, Ltd. headquarters. In FY2024, these self-assessments were continued*1, and the scope was expanded to include a manufacturing facility in China for the Nissei Business. Through these assessments, the Group reviewed its internal policies, procedures, and implementation status in response to RBA requirements. As a result of addressing any identified gaps, the Group confirmed that none of the assessed sites presented risks equivalent to a Priority Non-Conformance (PNC) in an on-site audit. Through these efforts, the Brother Group is working to ensure compliance with the RBA Code of Conduct*2 at its manufacturing facilities. At the same time, the Group is also committed to the "Pursuing a responsible value chain," one of the materialities identified by the Group, by using self-assessments to detect risks and minimize their potential impacts.

- 16 sites assessed in FY2024

Brother Industries (Vietnam) Ltd., Brother Industries (Philippines), Inc., Brother Technology (Shenzhen) Ltd., Zhuhai Brother Industries, Co., Ltd., Brother Industries (U.K.) Ltd., Brother Industries (Slovakia) s.r.o., Brother Industries (U.S.A.) Inc., Mie Brother Precision Industries, Ltd., Brother Machinery Xian Co., Ltd., Nissei Corporation, Nissei Gear Motor Mfg. (Changzhou) Co., Ltd., Taiwan Brother Industries, Ltd., Brother Industries Saigon, Ltd., Brother Industries, Ltd. (Headquarters, Hoshizaki Factory, Kariya Factory) - Contact for consultation if you become aware of a situation in the supply chain where there may be a violation of the "ethics" section of the RBA Code of Conduct

[brothersupplier.report@brother.co.jp]

For the ethics section of the RBA Code of Conduct, please see the RBA Code of Conduct

[Notes]

- Verification of your identity may be required depending on the nature of the consultation. If we are unable to verify your identity, we may not be able to provide consultation. We appreciate your understanding.

- Please make sure that you can receive our replies from the domain "@brother.co.jp."

- Please note that we will not be able to respond to inquiries that are not related to the ethics section of the RBA Code of Conduct at this contact.

CSR Procurement Efforts

CSR Procurement Level-up Program

Developed CSR Procurement Level-up Program

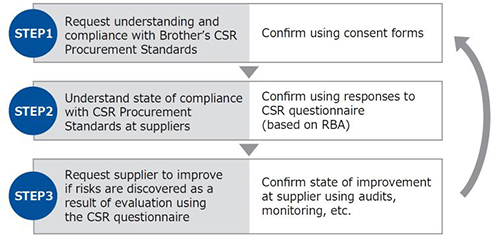

In FY2020, the Brother Group developed its CSR Procurement Level-up Program to improve CSR procurement at its suppliers. This program comprises the following three steps. Repeatedly following these steps helps improve the level of CSR procurement at each supplier. The program has evolved further since FY2023 as the information to be understood for consent changed from the Brother Group's CSR Procurement Standards to the RBA Code of Conduct to promote activities toward RBA compliance.

Regarding the RBA Code of Conduct, explanations are given to suppliers using supplementary information to help them understand and comply with it. Suppliers' consent to promote the activities is confirmed by signing a Confirmation Form.

The state of compliance with the RBA Code of Conduct is checked through self-checks using the CSR questionnaire (RBA-compliant). Risk assessment of suppliers is conducted based on the responses to the CSR questionnaire.

Suppliers that have risks discovered as a result of the assessment are requested to make improvements while ensuring meetings and other communication situations. The state of improvement is checked by combined means of audits and monitoring, and support for improvement activities is provided.

This program is being deployed not only for existing suppliers but also new ones. For existing suppliers, based on the evaluation results about the state of compliance with the RBA Code of Conduct, areas of improvement are clarified for each supplier, the results are given as feedback to the suppliers, and they are requested to make improvements. For new transactions, compliance with the RBA Code of Conduct is confirmed so that CSR procurement is carried out even more steadily in the future. Through this program, the Brother Group seeks to further improve the level of CSR procurement together with suppliers.

Details of Activities under and Results of the CSR Procurement Level-up Program

STEP1: Understanding and Consent; Activities to promote awareness of the RBA Code of Conduct

The Brother Group requests suppliers of its manufacturing facilities (P&S Business) to understand and comply with the RBA Code of Conduct.

To ensure understanding and compliance, the Group has prepared and is providing supplementary information to the RBA Code of Conduct, listing requests and matters it would like its suppliers to cooperate in so as to facilitate further understanding among its suppliers. The Group confirms suppliers' consent to promote the activities by obtaining their signatures on Confirmation Forms. In FY2023, the Group received consent from 649 business partners both in and outside Japan. In addition, when starting new transactions, the Group explains the RBA Code of Conduct to obtain understanding and cooperation.

In April 2025, we held supplier explanatory meetings at manufacturing facilities (P&S Business) in Japan, Vietnam, the Philippines, and China. On-site—and also online—explanatory meetings were held with a total of 924 participants from 504 supplier companies.

These meetings explained the "CSR procurement activity results for FY2024" and "CSR procurement activity plans for FY2025." We also informed supplier partners that, starting in FY2025, the annual CSR questionnaire survey will be conducted using an online system. These meetings served as an opportunity to deepen engagement with them.

Brother Group widely communicates the importance of CSR procurement to its suppliers. In FY2022, we asked our parts and materials suppliers in the P&S Business to appoint two or more CSR procurement personnel*. In FY2023 and FY2024, we worked with the appointed CSR procurement personnel at each supplier to help them formulate their own CSR Procurement Standards that specify information in the areas of labor, health and safety, the environment, and ethics. In formulating these standards, CSR procurement staff at the Brother Group's manufacturing facilities engaged in direct dialogue with their counterparts at supplier companies, clearly explaining the outline and purpose of the CSR Procurement Standards. Through these direct conversations, they helped clarify any uncertainties and areas for improvement related to the formulation process, thereby deepening suppliers' understanding of CSR procurement. In FY2024, materials related to CSR Procurement Standards and related activities were shared with suppliers of 19 companies to help them better understand CSR procurement. In addition, to promote awareness of the RBA Code of Conduct, Brother Industries (Philippines) Inc. provided its eight new suppliers with an e-learning course on the RBA.

- For P&S Business manufacturing facilities

STEP2: Confirmation of compliance and assessment; Conduct of CSR questionnaire and risk assessment of suppliers

The Brother Group implements CSR questionnaire activities on a two-year cycle for suppliers in Vietnam, the Philippines, China, and Japan, where the manufacturing facilities of the P&S Business are located. In FY2020, we revised our CSR questionnaire to check the state of compliance with the RBA Code of Conduct at our suppliers. The revised CSR questionnaire comprises questions in the five areas of labor, health and safety, the environment, ethics, and management systems. The questionnaire is configured to check the state of efforts at suppliers by means of self-checks. For example, in the area of labor, the items being checked include the absence of forced labor and child labor and compliance with local labor laws and regulations. In FY2024, we conducted a CSR questionnaire with 114 major suppliers in Vietnam, China, and Japan to conduct a risk assessment.

Together with the CSR questionnaire, we also sent questions about global environmental conservation to check the state of efforts at our suppliers regarding their activities to reduce greenhouse gas emissions. We asked suppliers to provide numerical values, such as the "greenhouse gas emissions (CO2 equivalent)" produced by their company and "reduction of the volume of water intake." Some suppliers also set their reduction targets in these categories and report on the degree of achievement of the targets.

| Risk rating | Score | Description |

|---|---|---|

| Low risk | 85 pts. or higher | Meets the "CSR Procurement Standards" requested by Brother |

| Moderate risk | 65 to 85 pts. | Some areas require improvement, but voluntary improvements can be made. |

| High risk | 65 pts. or lower | Has areas that require improvement, and needs immediate improvement and monitoring. |

STEP3: Improvement activities and audits; Conduct of CSR procurement audits

We request improvement and review the results of improvement activities from suppliers that are found to have risks in the CSR questionnaire. In FY2024, we provided feedback on the evaluation results to all suppliers that completed the CSR questionnaire, and conducted individual interviews with suppliers according to the evaluation results, requesting improvement and reviewing the results of improvement activities from suppliers that were found to have risks. For those suppliers that were found to be at risk, we requested them to make improvements and confirmed the results.

Besides requesting improvements from suppliers with risks discovered through the CSR questionnaire, we have also built a system where the Brother Group auditors conduct CSR procurement audits on suppliers' manufacturing facilities and get them to rectify any nonconformities that are discovered.

In FY2024, CSR procurement audits were conducted on 19 suppliers identified to be audited according to the results of CSR questionnaire assessment. Five suppliers in Vietnam, eight in the Philippines, and five in China, all of which we newly conduct business with, were audited in the areas of labor, ethics, health and safety, and management. For each nonconformity found as a result of the audit, Brother Group auditors explained the causes of the nonconformity and the measures required to become compliant, giving specific examples, and asked suppliers to take corrective actions.

Through these activities, the Brother Group seeks compliance with the Procurement Policy and CSR Procurement Standards together with our suppliers.

Promoting CSR Activities at Suppliers in Part Through Workplace Visits and the Selection of Outstanding CSR Activities

Implementing questionnaires on supplier CSR activities and visits to supplier companies at each manufacturing facility; Selected six Outstanding CSR Suppliers in China from submitted entries

Aiming to further promote the CSR activities of its suppliers, the Brother Group has been conducting questionnaire surveys about their CSR efforts, selecting and honoring excellent examples since 2015 at Machinery Business manufacturing facilities in Japan and China.

In China, a CSR questionnaire survey targeting suppliers was conducted between September and October 2024, and responses were received from 96 companies. In addition, CSR initiatives were solicited from suppliers, and among the 23 submissions received, six companies were selected and recognized with the Excellent CSR Award. One of the award-winning companies, which introduced energy-related equipment, was recognized not only for improving the working environment but also for contributing to the global environment by enhancing energy efficiency. This outstanding initiative was shared with other suppliers and Brother Group members who attended the award ceremony, providing an opportunity to learn from an excellent example.

The Brother Group continually strives to develop relations of mutual trust with its business partners and grow together with them to quickly deliver superior value to customers.

FY2024 award-winning company

BROTHER MACHINERY XIAN CO., LTD., Outstanding CSR award

- TAISEI(SHANGHAI)ELECTRONICS CO.,LTD

- NINGBO YINZHOU HANGSHAN MACHINERY MANUFACTURING CO.,LTD

- CHONGQINGZERO- ONE PRECISION MACHINERY CO., LTD

- FOUNDER MICRO MOTOR(LISHUI) CO.,LTD

- WU XI PERUN RUBBER&PLASTIC CO.,LTD

- SUZHOU JINYI PRECISION GEAR CO., LTD

Establishment of the Centralized Procurement Dept.

Under the three-year medium-term business strategy "CS B2027" for FY2025–FY2027, which aims to strengthen the Brother Group's management foundation by enhancing company-wide procurement management and other initiatives, the Centralized Procurement Dept. was established in April 2025 to oversee procurement operations in an integrated manner and execute them efficiently in collaboration with related departments. By formulating and implementing procurement strategies across all business segments—including the industrial domain—the department is working to strengthen the Group's overall procurement capabilities. Specifically, the new department aims to enhance supplier governance by centralizing information on management, human rights, and environmental initiatives; improve procurement stability by visualizing risk components* across all businesses and establishing a BCP framework; and reduce costs by supervising procurement processes from the upstream stages across all businesses and promoting centralized purchasing.

- Components that may affect the quality, safety, or reliability of products

Data Related to CSR Procurement

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|

| Procurement Policy and CSR Procurement Standards | Established in 2008 | ||||

| Green Procurement | Started in 2001 | ||||

| Supplier meeting | Conducted online Participated in by 217 people from 129 companies |

Conducted online Participated in by 680 people from 380 companies |

Conducted online Participated in by 814 people from 478 companies |

Conducted on-site and online Participated in by 842 people from 472 companies |

Conducted on-site and online Participated in by 734 people from 408 companies |

| CSR questionnaire | Started in 2012 (conducted every three years), revised in 2020 (conducted every two years) | ||||

Policy on the Responsible Procurement of Minerals

A part of the minerals (tantalum, tin, gold and tungsten, cobalt, mica, etc.) mined in conflict-affected and high-risk areas, such as the Democratic Republic of the Congo and adjoining countries are some sources of funds for local armed groups, and there are concerns that transactions for such minerals may promote conflicts and involve matters such as human rights violations, labor issues and environmental degradation problems.

In promoting management with an emphasis on sustainability, the Brother Group recognizes the human rights violation, labor rights violation, environmental degradation, etc. in mining and trade of those minerals as important social issues.

To implement responsible procurement of minerals, the Brother Group carries out surveys on the use of aforementioned conflict minerals and will steadily undertake efforts toward ensuring transparency of mineral procurement in the supply chain and avoiding the use of conflict minerals while cooperating with suppliers.

Efforts in the Brother Group to Practice the Responsible Procurement of Minerals

To promote responsible procurement of minerals across the Brother Group's entire supply chain, we are undertaking the following initiatives according to a five-step framework based on the "Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas" issued by the Organisation for Economic Co-operation and Development (OECD).

For the Brother Group's approach to the responsible procurement of minerals, we have examined systems and methods to engage in the responsible procurement of minerals since 2014 and have been carrying out conflict minerals surveys on tantalum, tin, gold, and tungsten (3TG) targeting suppliers since 2016. Starting in 2022, we have also begun conducting a mineral procurement survey for cobalt and mica.

Currently, under the Responsible Value Chain Subcommittee, a working group has been established with the participation of relevant departments, including those in charge of procurement and legal affairs. In addition, a Work Standard for mineral procurement surveys has been formulated to promote responsible mineral sourcing in a comprehensive manner. In addition, training is conducted for members in the working group and staff in the procurement and quality control departments responsible for the survey on the responsible procurement of minerals to improve their understanding of our mineral procurement survey initiatives.

The Brother Group has been carrying out a mineral procurement survey once a year targeting suppliers that supply materials or parts used in the Group's products. In this survey, the Group uses the "Conflict Minerals Reporting Template (CMRT)" as well as "Extended Minerals Reporting Template (EMRT)" provided by the Responsible Minerals Initiative (RMI)*1 to verify the content of the target minerals, identify smelters or refiners (SOR) in the supply chain of the Brother Group, and confirm the state of efforts made by each supplier toward the responsible procurement of minerals. Based on the information on SORs included in the Brother Group's supply chain identified as a result of the survey and other information, we conduct a risk assessment for each supplier.

Based on the results of risk assessment, we ask suppliers that use SORs expected to be of concern to take appropriate responses, including requiring suppliers to conduct reconfirmation of SOR and avoid use of SORs with concerns.

Furthermore, the Brother Group also requests that suppliers understand the Group's stances through means such as the CSR Procurement Standards and supplier explanatory meetings, and work on responsible procurement activities for minerals.

As a corporate member of RBA and RMI, Brother Group supports the Responsible Minerals Assurance Process (RMAP)*2 audits conducted by RMI, and cooperates with the industry to improve activities regarding mineral procurement surveys, and promotes responsible mineral procurement on a global basis in its supply chain.

Brother Group's commitment to the responsible procurement of minerals is disclosed annually on our website.

The Brother Group carried out the annual mineral procurement survey in 2024 and obtained answers from more than 98% of the targeted suppliers. The Group will make ongoing efforts to obtain answers from all of such suppliers.

The Group also appropriately answered and dealt with inquiries from customers about the procurement of minerals survey by means such as the submission of CMRT and EMRT.

| CY2020 | CY2021 | CY2022 | CY2023 | CY2024 | |

|---|---|---|---|---|---|

| Response rate | 95.5% | 97.4% | 97.1% | 98.5% | 98.1% |

| CY2023 | CY2024 | |||||

|---|---|---|---|---|---|---|

| Total | Tantalum | Tin | Tungsten | Gold | Total | |

| Number of identified SORs | 349 | 36 | 90 | 54 | 182 | 362 |

| Number of CFS*3 | 229 | 34 | 72 | 35 | 99 | 240 |

| Percentage of CFS*3 | 65.6% | 94.4% | 80.0% | 64.8% | 54.4% | 66.3% |

| CY2023 | CY2024 | |

|---|---|---|

| Number of identified SORs | 84 | 95 |

| Number of CFS*3 | 50 | 62 |

| Percentage of CFS*3 | 59.5% | 65.3% |

The Brother Group has had its four manufacturing facilities undergo RBA audits, which have been recognized to meet the required standards based on the RBA Code of Conduct (D. Ethics 7. Responsible Sourcing of Minerals).

For details on facilities with RBA recognition and related information, please refer to "Management with an Emphasis on Sustainability - Participation in External Initiatives".

- Responsible Minerals Initiative (RMI): An organization that promotes the responsible procurement of minerals globally in cooperation with companies.

- Responsible Minerals Assurance Process (RMAP): A third-party smelter/refiner audit and certification program operated by RMI

- Conflict-Free Smelters (CFS): Smelters or refiners that have been certified as not using conflict minerals through an RMAP audit, including those currently undergoing audits or committed to undergoing them