- Value Creation Activities

- "Value" Chain Starting with Customers

- Product Planning, Research and Development

- Development Design, Production Engineering

- Manufacturing, Distribution, Sales and Service

- Intellectual Property

Brother Develops a Product That Meets Customer Demands to Expand the Machine Tool Market

The Brother Group places customers first, demonstrating its "At your side." spirit in its approach to manufacturing. To contribute to even greater value creation at production sites, the Brother Group is responding quickly to customer demands and changes in the world including with the SPEEDIO series of machine tools.

To respond to customer needs, sales, technical, and service staff visit customers together to directly listen to their needs and consider what new functions and solutions should be proposed. Also, the manufacturing, quality assurance, and service departments work together with the development departments to advance multiple product development projects in parallel, thereby accelerating the development and launch of new products.

Deburring Center SPEEDIO DG-1, launched in September 2024, is a machine dedicated to deburring die-cast parts. While the conventional SPEEDIO machines were designed for parts processing, Deburring Center DG-1 is focused on removing burrs on materials that occur during the process of manufacturing die-cast parts. Deburring is mostly handwork, and in recent years, labor shortages have caused difficulty in securing workers for deburring. Moreover, deburring with robots or numerically controlled (NC) machining centers needs much time devoted to creating programs and modifying processing paths, resulting in demand for an easier and quicker start of processes. Our development staff witnessed customers facing these challenges at their operational sites many times, which drove them to find solutions. Since there was no machine tool based on the same concept on the market, the development staff repeated the process of producing a prototype, having it used by customers, and producing another prototype while listening to customer feedback in order to refine the specifications and functions of the tool. As a result, they finally succeeded in creating a product that made customers say, "This is the machine tool we've been looking for."

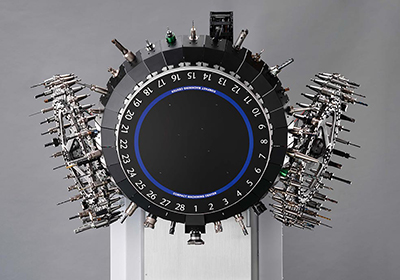

In addition, the SPEEDIO S700Xd2-100T and U500Xd2-100T, launched in March 2025, are the first models of compact machining centers that have a storage capacity of 100 tools. Over the period of more than 10 years before then, we had detected strong demand for high-mix, low-volume production through our visits to customers in Europe and other regions. We had since mulled over an idea for compact machine tools that could be mounted with 100 tools. The COVID-19 pandemic triggered a shift of the mainstream of parts processing, especially in the automotive industry, from mass production to high-mix, small-lot production, resulting in further growing demand for this kind of production. In mass production, the key to productivity improvement is to reduce the time needed to process each part. Meanwhile, productivity improvement in small-lot, high-mix production requires reducing the time needed to exchange jigs and tools. As a solution to this challenge, we developed a new "100-tool magazine" with a storage capacity of 100 tools. For example, it takes as short as five seconds to replace the tools in the magazine at the front of the console with those in the tool stockers on the left and right. These new models therefore feature a much more rapid exchange of tools.

The Brother Group will continue to develop products by listening to customer demands in order to provide optimal products that meet their needs, while leveraging its own strengths and expertise.

Corporate commercial "The Essence of Manufacturing"

BIL has released the corporate commercial "The Essence of Manufacturing," a documentary film showing the journey of a young Brother engineer who gains hints for manufacturing through dialogue with customers.

- This video is available only in Japanese