- Value Creation Activities

- "Value" Chain Starting with Customers

- Product Planning, Research and Development

- Development Design, Production Engineering

- Manufacturing, Distribution, Sales and Service

- Intellectual Property

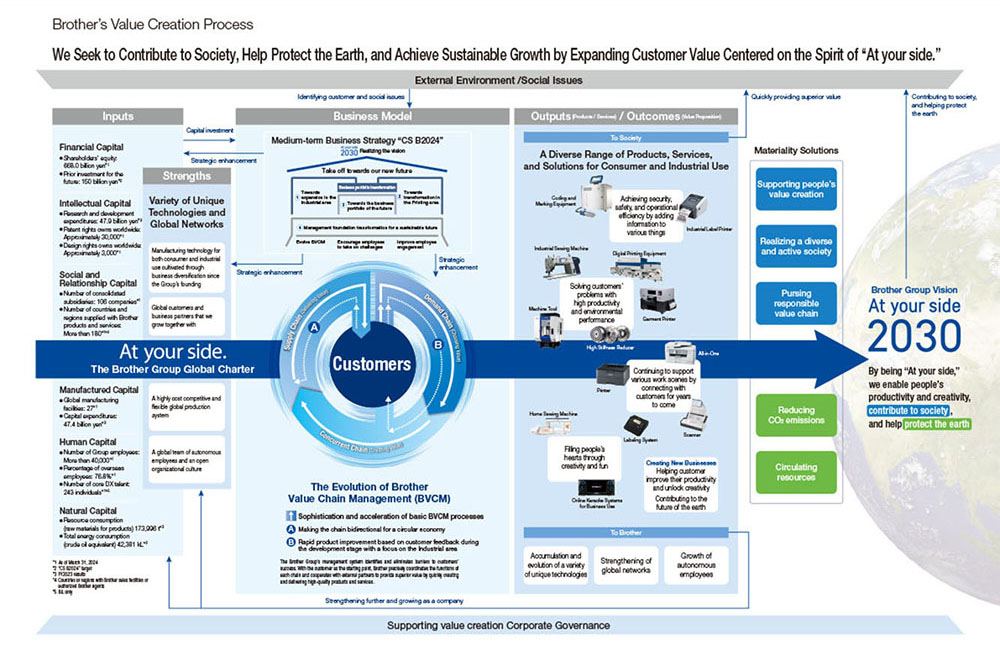

Brother's Value Creation Process

The source of the Brother Group's value creation comes from the spirit of "At your side."—the company spirit that places our customers first in every situation, every time. Under this spirit, the Brother Group companies all over the world provide a diverse range of products, services, and solutions for consumer and industrial applications by investing the six capitals and Brother's strengths, and by practicing Brother Value Chain Management (BVCM) which is Brother's unique customer-centric management system based on our medium-term business strategy. By addressing the six materialities, we support the productivity and creativity of our customers closely, contribute to society, and help protect the earth. Through this expansion of customer value, we will achieve sustainable growth as a company.

Brother's Strengths

Brother contributes to customers' ability to improve their productivity and unlock their creativity by making the most of a variety of unique technologies cultivated over its history of business evolution, as well as its global networks.

To support all those who wish to keep progressing, we will apply our strengths as a global company with multiple businesses, and while utilizing knowledge gained externally, we will create value, in addition to manufacturing products. In this way, we will help customers to realize their goals.

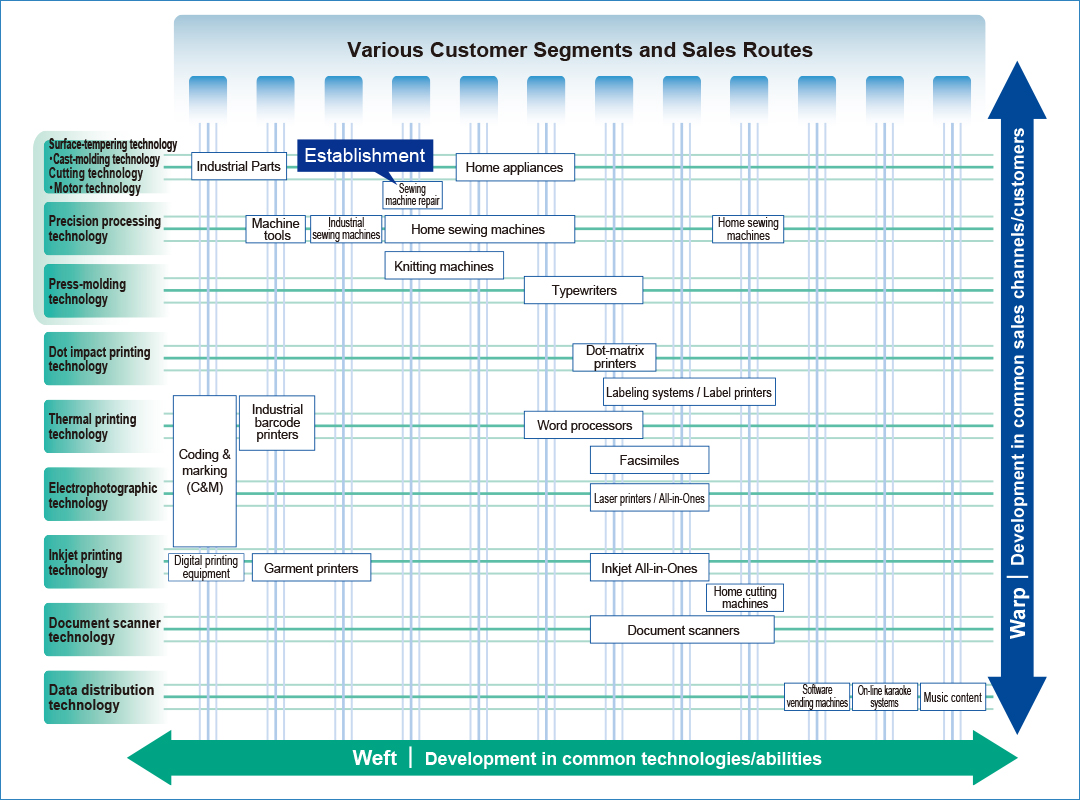

A Variety of Unique Technologies That Generate New Value

Since its foundation, Brother has generated new businesses by utilizing commonalities between various customer segments and sales routes and technologies and capabilities in order to meet the changing needs of customers and markets. We have used this continuity as the warp and weft and broadened our business scope by weaving the threads. This breadth, along with a corporate culture enabling collaboration across business domains and new value creation through the combination of technologies, are the unique strengths of Brother.

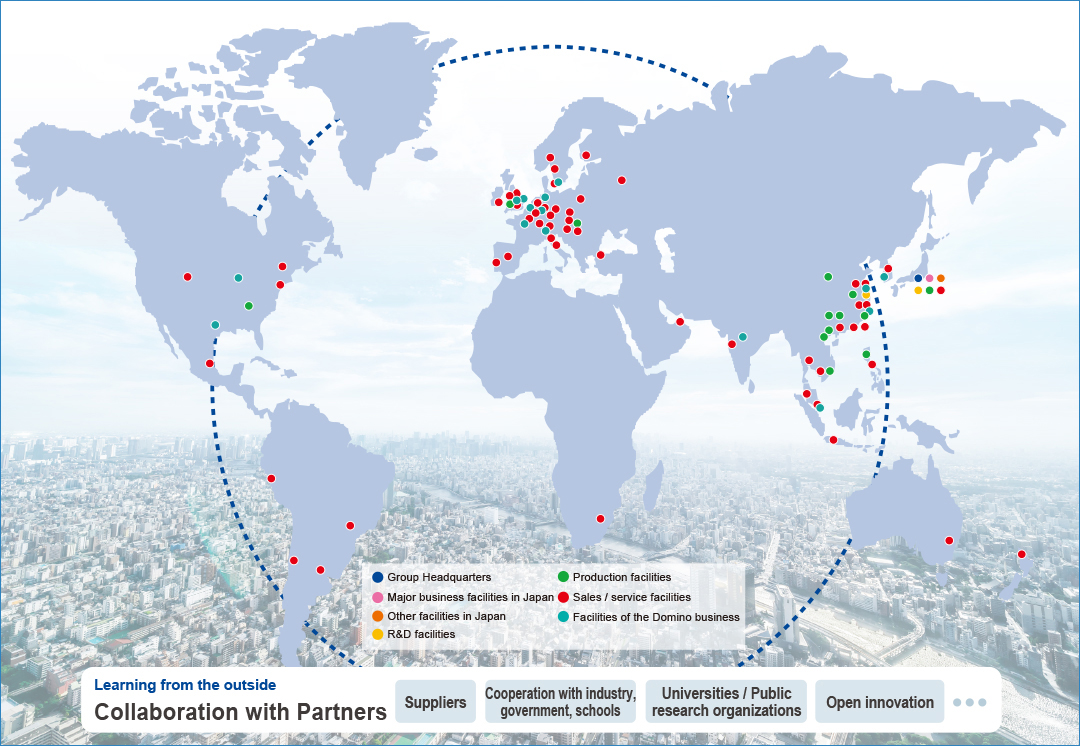

Global Networks That Enable Us to Meet Needs and Provide Value Promptly

To date, Brother has expanded its facilities for development, production, sales, and services in more than 40 countries and regions. Utilizing these global networks, we have developed flexibility to meet customer needs, agility to provide products and services quickly, and cost competitiveness based on efficient networks. These are also part of our strengths. We will continue to leverage knowledge gained externally and collaboration with partners and provide outstanding value promptly through the collective efforts of the Brother Group companies in Japan and overseas.

Brother's Capitals

|

Integrated Report

|

|

|---|---|

|

Intellectual Capital 32 page ■Capital status

Research and development expenditures:

A variety of unique technologies |

Social and Relationship Capital 34 page ■Capital status

Number of consolidated subsidiaries:

Global customers and business partners that we grow together with |

|

Manufactured Capital 33 page ■Capital status

Global manufacturing facilities: 28*1

Highly cost-competitive and flexible global manufacturing system |

Human Capital 30-31 page ■Capital status

Number of Group employees: More than 40,000*1

A global team of autonomous employees and an open organizational culture |

|

Natural Capital 35 page ■Capital status

Resource consumption (raw materials for products) 207,760 t*1

|

|

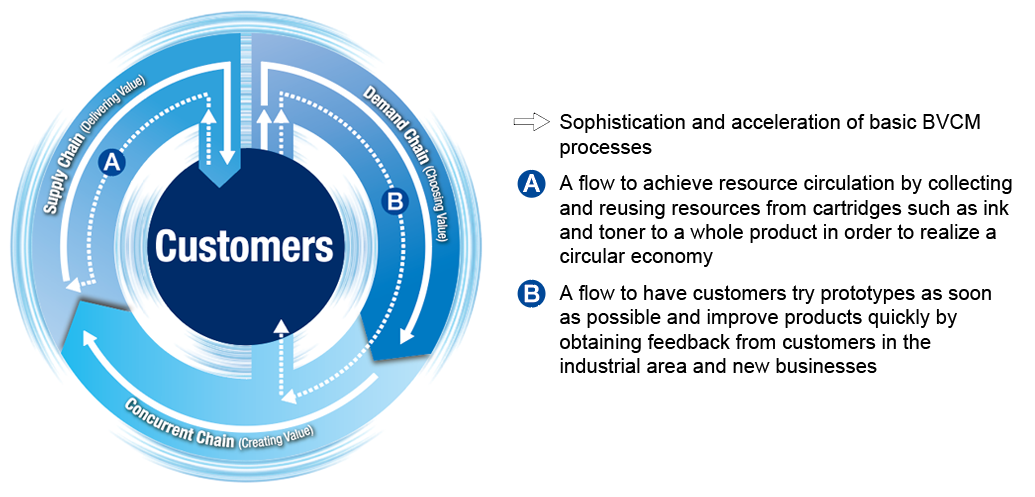

Brother Value Chain Management

The Brother Group considers customer demands and expectations top priority as our guide for all of our business operations including product planning, development, design, manufacturing, sales, and service, and we have established and practice our unique Brother Value Chain Management (BVCM) system in order to deliver superior value quickly. The Group aims to maximize the value it provides by continuing to evolve the BVCM.

Basic BVCM processes

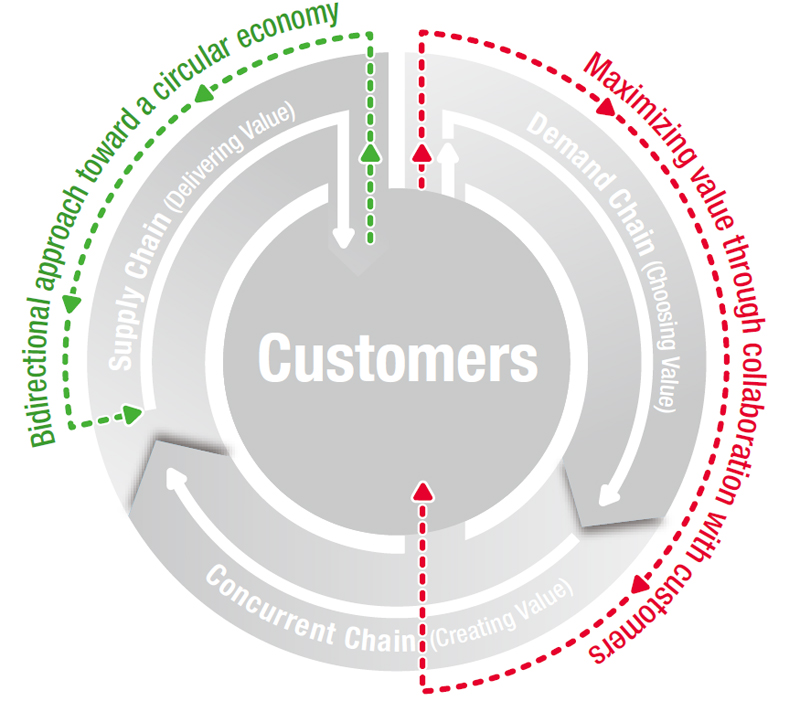

Brother achieves flexible and swift value creation through the BVCM, a process for delivering superior value to customers, consisting of three chains: the Demand Chain, the Concurrent Chain, and the Supply Chain. By accelerating the circulation of this customer-oriented value chain, we are able to quickly deliver superior products, services, and solutions.

Customer

"Value" chain starting with customers

The opinions of "existing" customers who have already purchased Brother products and "potential" customers who may purchase Brother products in the future are the starting point for all our business activities.

Our call centers, which serve as our important points of contact with customers, receive various inquiries and requests from them. We register such information in our database and share it globally across the entire Brother Group.

Demand Chain (Choosing Value)

- Understand the true needs of customers on a global basis and determine our unique value to provide

- Planning and development departments work together to determine the best way to create and deliver value

Based on opinions received by call centers around the world and information acquired through sales and service activities and marketing surveys, sales and development departments work together to analyze customer expectations and demands from various angles, such as "how product use environments will change," and "what improvements would satisfy more customers." Through these efforts, they formulate product concepts.

Specific examples related to product planning and research and developmentConcurrent Chain (Creating Value)

- Design departments (for machinery, electricity & electronics, software, chemicals, etc.), manufacturing departments, and suppliers work in close collaboration

- Utilize an optimal combination of internal and external technologies

Product concepts created in the demand chain are given a concrete shape. Product simulations and focus group testing by intended users are run again and again before and after prototyping. Through this process, we develop and design our products speedily while ensuring high product quality. The production engineering department designs optimal production lines to deliver our products at the right time for our customers.

Specific examples related to development design and production engineeringSupply Chain (Delivering Value)

- Refine cost competitiveness and adaptability to changes, and manufacture the best products in the best regions

- Provide detailed sales and services based on a thorough understanding of the characteristics of customers in each country and region

At the Brother Group's manufacturing facilities, we are working closely with business partners, such as parts suppliers, and strengthening manufacturing processes and quality control systems, so as to produce high quality products. Products are delivered to customers through our sales facilities in countries and regions all over the world. We are also providing customers with swift, cordial support via online support over the Internet and call centers in order to make each individual satisfied.

Specific examples related to manufacturing, distribution, sales and serviceEvolution of BVCM

In order to realize the Brother Group Vision's goals of "promoting circular-economy-based business" and "expansion in the Industrial area," we have taken the basic BVCM process (solid white line) and added the green dotted line signifying "Bidirectional approach toward a circular economy" and the red dotted line signifying "Maximizing value through collaboration with customers." Along with the basic process, we will pursue further advancement of these approaches.

Bidirectional approach toward a circular economy (Green dotted line)

Flow to achieve resource circulation by collecting and reusing

The Brother Group is helping society achieve sustainable development by positively and continuously considering the environmental impact in all aspects of our business operations. Concern for the environment shall be the cornerstone of all operations. The green dotted line represents the realization of resource circulation based on consideration of safety and environmental impact throughout all stages of the product lifecycle, from product development and design to manufacturing, customer use, disposal, and reuse. With "the end of life" of products in mind, the Brother Group has been working to (i) increase the reusability and recyclability of products and consumables and (ii) build recycling systems.

- Printing Business Develops its Ink Cartridge Remanufacturing Capabilities

- Collection, Remanufacturing and Recycling Efforts in Various Countries

Maximizing value through collaboration with customers (Red dotted line)

Flow to improve products quickly by obtaining feedback from customers

This represents the process of having customers try prototypes early in the development stage, obtaining feedback, and quickly improving the product, with the aim of realizing "expansion in the Industrial area" and creation of new businesses. For example, to contribute to even greater value creation at production sites, the Brother Group responds promptly to customer demand, as demonstrated by the machine tool SPEEDIO Deburring Center DG-1.