- Progress Toward Resource Circulation, Waste Reduction and Water Reduction Targets

- Resource Circulation and Waste Reduction Initiatives in Products

- Resource Circulation and Waste Reduction Initiatives in Productions

- The Brother Group's Water Usage Reduction Activities

- Water Intake, Wastewater Volume, Volume of Water Recycled

- 2025 CDP Questionnaire

The vision aims to ensure sustainable use of resources in business operations and minimize the environmental impact due to wastes.

Toward 2050, the Brother Group will maximize resource circulation to ensure the sustainable use of resources and to minimize the environmental impact due to wastes.

Main efforts: Expansion of circular-economy-based businesses, reuse of products and parts, use of recycled materials, etc.

Progress Toward Resource Circulation, Waste Reduction and Water Reduction Targets

Two medium-term targets for FY2030 regarding resource circulation are set in the Brother Group Environmental Vision 2050. To achieve these targets, we are working to reduce waste and water usage by promoting resource circulation in our manufacturing and production activities.

Medium-term target for FY2030 (Previous medium-term targets before revision on March 3, 2025. The period covered is from FY2022 to FY2024 of CS B2024.)

- Reduce the ratio of virgin materials used in products*1 to 65% or less*2 by FY2030 through the expansion of circular-economy-based businesses and materials recycling.

- The group's manufacturing facilities continuously endeavor to ensure efficient use of water resources and proper treatment of wastewater.

- Including packaging materials

- Applies to the Printing and Solutions Business, Machinery Business, and Personal and Home Business

We have worked to promote resource circulation to reduce the ratio of virgin materials used in products to 81% or less, which is the target for FY2024 set in CS B2024. In FY2024, the ratio of virgin materials was confirmed to be 79.3% through verification of the amounts of virgin materials used in our products by a third party. Therefore, the target for FY2024 has been achieved.

We are also working to achieve efficient use of water resources, and ensure proper treatment of wastewater.

Resource Circulation and Waste Reduction Initiatives in Products

The Brother Group engages in resource circulation to address the environmental issues resulting from resource use, such as depletion of natural resources and pollution by waste, etc., as well as to reduce CO2 emissions.

Specifically, we aim to reduce the amount of virgin materials used in products by 25% from FY2022 levels in FY2025 and beyond by increasing the proportion of recycled plastic materials used in our products, replacing plastic parts to paper-based materials, and promoting the use of reused goods.

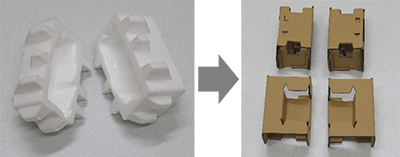

Eco-conscious toner cartridge package

Previously, polystyrene foam was used as cushioning parts and materials for toner cartridges. However, it has been replaced by cushioning parts and materials made from corrugated fiberboard as an initiative to reduce the consumption of plastics.

The use of corrugated fiberboard, which can be easily recycled, also contributes to improving recyclability.

- This initiative started in April 2024 for some products in Japan. The scope of applicable products will be expanded in stages.

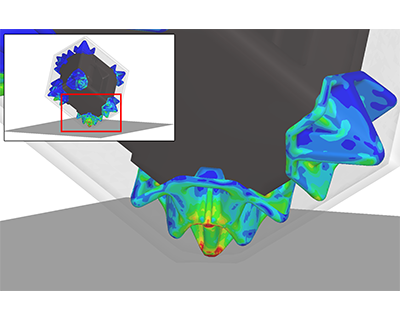

Compact and lightweight molded pulp cushioning material

Conventional cushioning materials entirely covered products. Brother Industries' engineering capabilities have reduced their size and resource consumption, achieving a 33% reduction in CO2 emissions from cushioning materials and a 7% reduction in the volume of product boxes. Furthermore, drop simulations were used for Brother's proprietary molded pulp cushioning material, making it possible to reduce the number of prototype iterations, significantly shorten the development period, and improve the design efficiency.

Exploring recycling possibilities for the sake of the future global environment

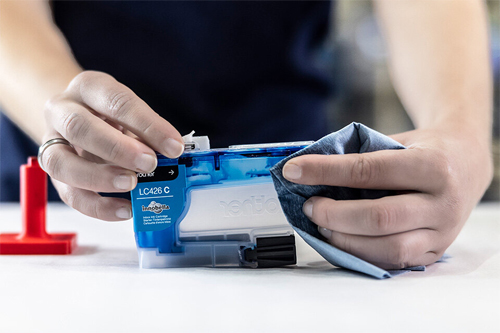

In Europe, we started a recycling program in 2004 by adopting newly developed recycling-compatible toner cartridges.

Thanks to an automated recycling system we introduced, we are able to offer the same high quality in recycled cartridges, as well.

In 2014, the Brother Group received two prestigious awards in the 2014 Responsible Business Awards given out by Business in the Community, a U.K.-based NPO. The group's contribution to communities and the environment was recognized.

Contents of SDGs STORY

Resource Circulation and Waste Reduction Initiatives in Productions

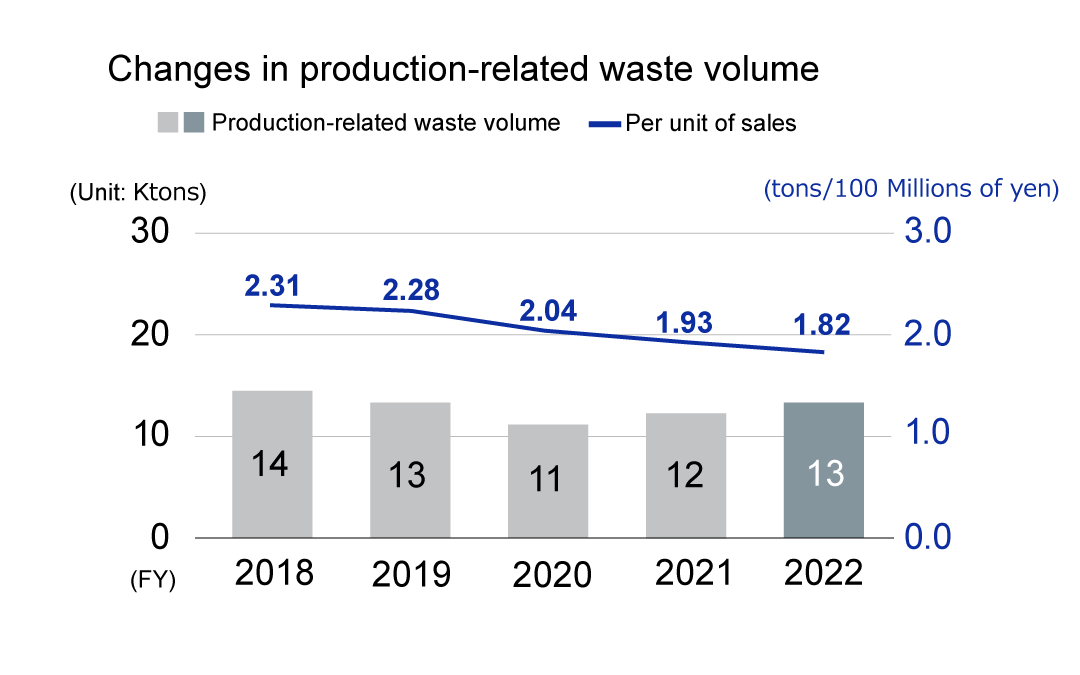

Due to ongoing waste reduction efforts, the amount of waste per unit of sales was reduced year by year from FY2019 to FY2023. However, in FY2024, production volume and the number of employees increased at Brother Industries (Philippines), Inc., and ink waste liquid also increased at the Hoshizaki Factory, compared to the previous fiscal year. As a result, the amount of waste per unit of sales increased by approximately 4.5%. In FY2024, the total amount of plastics generated by BIL was 519 tons, which was an increase of approximately 1% compared to the FY2023 level.

Brother Machinery Xian Co., Ltd. introduced a vacuum distillation waste liquid treatment system equipped with a highly efficient heat circulation function, which reduced the amount of waste liquid by approximately 88%. The factory also continues to reuse waste cloth. Brother Technology (Shenzhen) Ltd. uses waste materials generated from the plastic parts molding process in the factory as the material to manufacture returnable containers and other items.

In FY2024, hazardous waste (specially controlled industrial waste) increased from the previous fiscal year. This was due to a temporary increase in waste generated in line with the relocation of a building of the Hoshizaki Factory. A specially controlled industrial waste management plan will be submitted to the local government to promote systematic reduction.

Waste liquid treatment system

| FY2022 | FY2023 | FY2024 | |

|---|---|---|---|

| Volume of hazardous waste(t) | 55.0 | 68.3 | 76.9 |

The Brother Group's Water Usage Reduction Activities

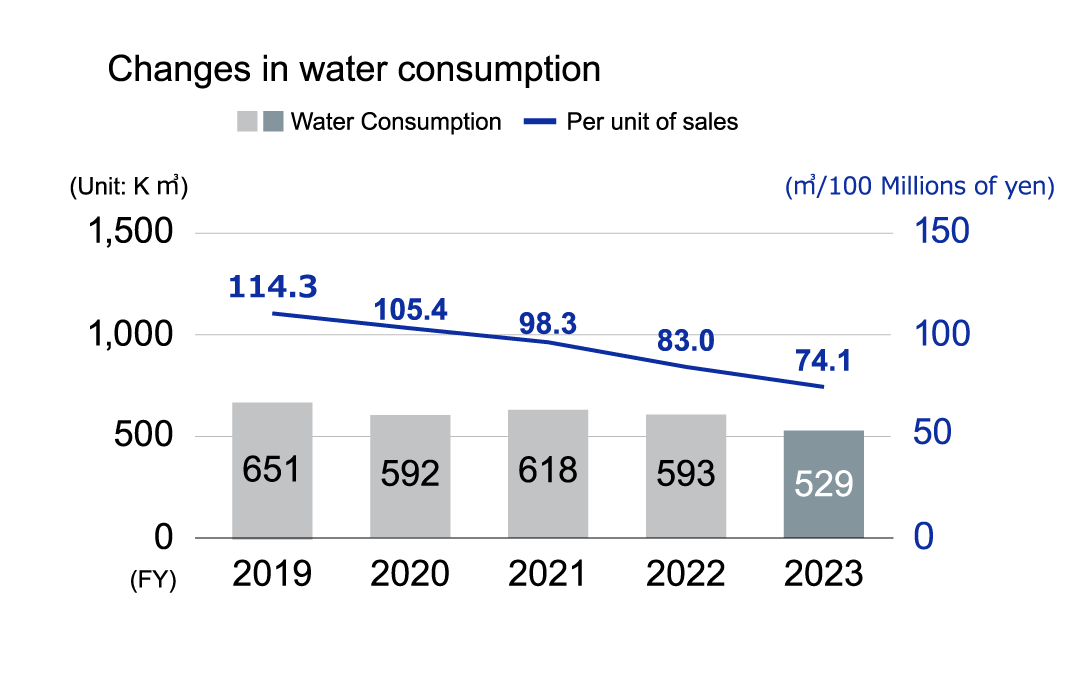

Securing safe water resources is an important environmental challenge common across the globe. The Brother Group has been monitoring all of our sites regularly, evaluating water risks at each site every year, and working to reduce water consumption to fulfill our responsibilities as an operator of manufacturing facilities in many countries and regions. At the 13 facilities with relatively higher water consumption, we formulate water management plans and implement various initiatives.

The Brother Group's manufacturing facilities have been working to reduce the amount of water intake by improving the water recycling rate. Brother Machinery Xian Co., Ltd. uses wastewater from a water feeder to wash cleaning tools. Brother Technology (Shenzhen) Ltd. and Brother Industries Saigon, Ltd. reuse water that had been used for inspecting water leakage from containers and wastewater from air conditioning systems. Brother Industries (Vietnam) Ltd. contributes to reducing the amount of water intake by using treated wastewater from the wastewater treatment system for toilets.

In addition to the above recycling activities, Brother Technology (Shenzhen) Ltd. improves the water spraying equipment, introduces new cleaning methods, installs automatic taps, and promotes the use of rainwater.

As a result of increased business activities in FY2024, water usage per unit of sales at major manufacturing facilities rose by approximately 6.5% compared to the previous fiscal year.

Water circulation efforts at Brother Machinery Xian Co., Ltd.

Brother Machinery Xian Co., Ltd. (BMX) is located in an area with relatively high water risk since water resources are not abundant there. In FY2018, as part of an effort to circulate water, BMX installed a rainwater collection tank inside its site and is continuing to use the collected water for maintaining greenery.

- Revised the calculation based on the unit-of-sales ratio.

Scope of aggregation

| After FY2018 |

|---|

| Eight business sites in Japan (head office of Brother Industries, Ltd., Mizuho Factory, Hoshizaki Factory, Minato Factory, Momozono Factory, Kariya Factory, Research & Development Center, and Logistics Center), Nissei Corporation, Nissei Gear Motor MFG. (Changzhou) Co., Ltd., Mie Brother Precision Industries, Ltd., Brother Industries (U.K.) Ltd., Brother Industries (Slovakia) s.r.o., Taiwan Brother Industries, Ltd., Zhuhai Brother Industries, Co., Ltd., Brother Machinery Xian Co., Ltd., Brother Technology (Shenzhen) Ltd., Brother Industries (Philippines), Brother Industries (Vietnam) Ltd. and Brother Industries Saigon, Ltd., Inc. |

Water Intake, Wastewater Volume, Volume of Water Recycled

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | ||

|---|---|---|---|---|---|---|

| Water intake(m3) | Clean water | 504,122 | 506,166 | 470,172 | 408,991 | 446,818 |

| Industrial water | 0 | 0 | 0 | 0 | 0 | |

| Underground water | 87,474 | 111,697 | 123,034 | 119,904 | 151,316 | |

| Wastewater volume(m3) | Public waters | 179,782 | 170,392 | 150,453 | 110,928 | 126,247 |

| Sewer system | 338,746 | 372,721 | 369,193 | 333,406 | 375,282 | |

| Other | 1,177 | 150 | 149 | 36 | 0 | |

| Volume of water recycled(m3) | 3,759 | 2,978 | 5,385 | 8,717 | 16,354 | |

| Percent of water recycled(%) | 0.7 | 0.5 | 1.0 | 1.9 | 3.2 | |

For the list of applicable sites, see page 5 of "Material balance" [PDF/239KB].

2025 CDP Questionnaire

CDP (formerly Carbon Disclosure Project) is an international non-profit environmental organization founded in 2000, whose disclosure system has become the global standard for environmental disclosure in the world economy.

CDP's environmental data is used by financial markets, policy initiatives, and various other stakeholders.

Brother Industries, Ltd. has been participating in CDP Climate Change since 2011 and CDP Water Security since 2015, and responding to the questionnaires.

- In 2024, questions regarding Climate change, Forests, Water security, Plastics, and Biodiversity were integrated into the CDP Questionnaire.