- Progress Towards CO2 Emission Reduction Targets

- Scopes 1, 2, and 3 Greenhouse Gas (GHG) Emissions

- External Assurance

- Efforts to Reduce CO2 Emissions in Business Sites

- Efforts to Reduce CO2 Emissions in Products

- Collaboration with Suppliers

- Contribution to CO2 Reduction for Society as a Whole through Products

- External Award (Energy Conservation Grand Prize)

- 2025 CDP Questionnaire

The vision aims to support the Paris Agreement and contribute toward creating a carbon-free society with zero greenhouse gas emissions.

The Brother Group will aim to achieve carbon neutrality* in all business operations and minimize CO2 emissions from the entire value chain by 2050 so as to contribute toward creating a carbon-free society.

- Achieve overall zero CO2 emissions from the Brother Group

Main efforts: Introduction of solar power generation, renewal of air conditioning facilities, renewal and adoption of energy-saving for production facilities, etc.

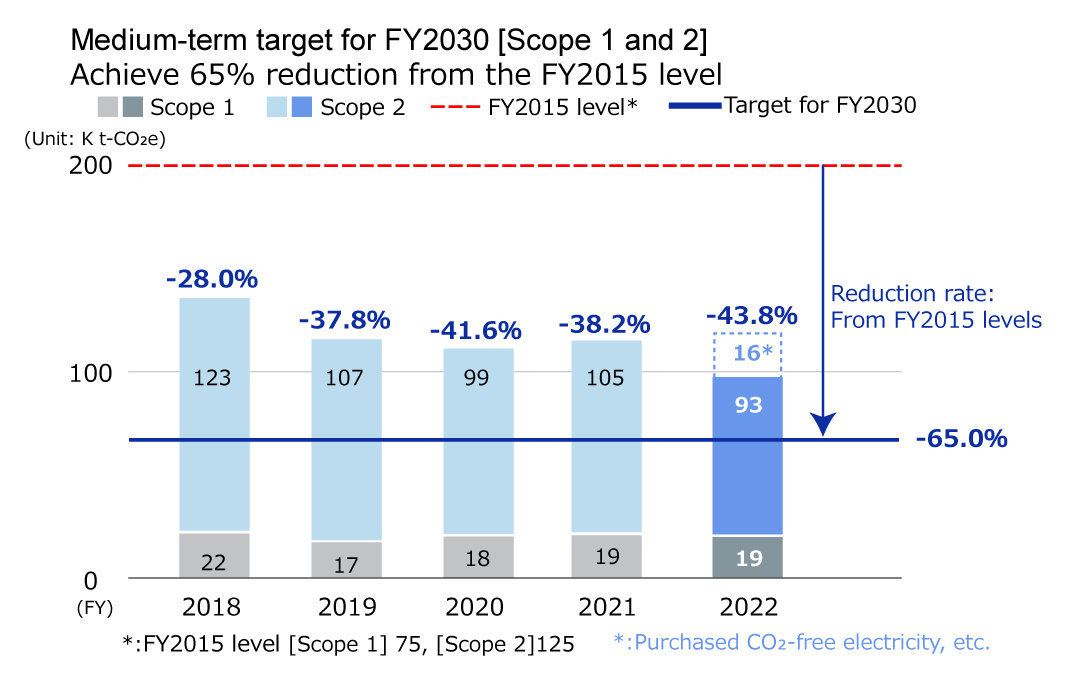

Progress Towards CO2 Emission Reduction Targets

Two medium-term targets for FY2030 regarding CO2 emission reduction are set in the Brother Group Environmental Vision 2050. To achieve these targets, we are working to reduce CO2 emission with supplier collaboration in our manufacturing and production activities.

Medium-term target for FY2030 (Previous medium-term targets before revision on March 3, 2025. The period covered is from FY2022 to FY2024 of CS B2024.)

- [Scopes 1 and 2] Achieve 65% reduction from the FY2015 level

- [Scope 3] Categories 1, 11, and 12 Achieve 30% reduction from the FY2015 level

- The medium-term target for FY2030 has been recognized as a target based on scientific evidence (1.5°C target) by the Science Based Targets initiative (SBTi), an international initiative established to help achieve greenhouse gas emission reduction targets.

We worked to promote reduction of CO2 emissions by 47% from the FY2015 level for Scopes 1 and 2 and implement measures to reduce CO2 emissions by 150,000 tons for categories 1, 11, and 12 of Scope 3, which are the targets for FY2024 set in CS B2024.

In FY2024, for Scopes 1 and 2, we achieved 49.7% reduction from the FY2015 level. Regarding Scope 3, while expanding sales of new products, whose environmental performance is higher than that of conventional products, we reduced CO2 emissions in the parts procurement phase by 30,000 tons in three years in collaboration with suppliers. As a result of these efforts, categories 1, 11, and 12 saw a 21.2% reduction compared to FY2015

Progress up to FY2024

Scopes 1, 2, and 3 Greenhouse Gas (GHG) Emissions

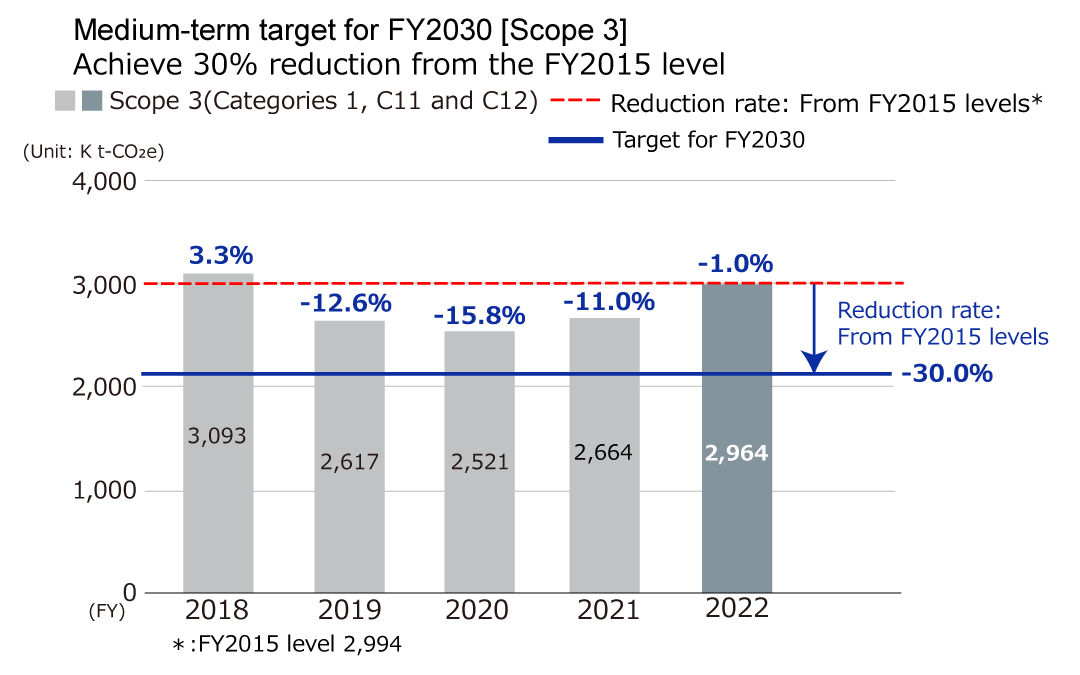

The Brother Group calculates and reports Scope 1, 2, and 3 greenhouse gas (GHG) emissions based on the GHG Protocol and Ministry of the Environment's guidelines for calculating emissions in order to properly calculate and report its GHG emissions. Furthermore, the calculation results are verified by a third party in accordance with ISO 14064-3 standards to confirm the reliability of the results before they are made public.

Scope 1, 2, and 3

These are components making up greenhouse gas (GHG) emissions in the supply chain. Dividing into three categories minimizes overlapping calculations and allows specific emissions to be identified.

Scope 1: Direct GHG emissions by business operators

Scope 2: Indirect GHG emissions resulting from use of electricity, heat, and steam supplied by other entities

Scope 3: Indirect GHG emissions other than Scope 1 and 2 (emissions by other entities related to the activities of business operators)

Scope 1, 2, and 3 greenhouse gas (GHG) emissions according to ISO 14064 from FY2020 through FY2024

| Category | CO2 emissions in t-CO2e equivalent | |||||

|---|---|---|---|---|---|---|

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | ||

| Scope 1: Direct emissions | 18,356 | 18,724 | 19,040 | 18,840 | 17,850 | |

| Scope 2: Indirect emissions from energy use Market-based | 98,685 | 105,099 | 93,409*1 | 91,228*1 | 82,897*1 | |

| Scope 3: Other indirect emissions | 2,752,567 | 2,942,352 | 3,439,056*2 | 2,431,462*1 | 2,633,871*1 | |

| C1 | Purchased goods and services | 1,302,661 | 1,404,939 | 1,671,015*2 | 1,253,780*1 | 1,411,041*1 |

| C2 | Capital goods | 75,897 | 86,955 | 123,562 | 126,268 | 119,606 |

| C3 | Fuel- and energy-related activities | 10,987 | 11,838 | 12,062 | 11,899 | 12,130 |

| C4 | Upstream transportation and distribution | 103,148 | 138,978 | 99,236 | 95,109 | 90,402 |

| C5 | Waste generated in operations | 4,138 | 2,849 | 3,257 | 3,991 | 8,822 |

| C6 | Business travel | 1,558 | 1,887 | 4,023 | 6,502 | 6,673 |

| C7 | Employee commuting | 14,698 | 14,819 | 14,768 | 15,553 | 16,574 |

| C8 | Upstream leased assets | 4,642 | 4,101 | 3,827 | 4,588 | 4,316 |

| C9 | Downstream transportation and distribution | 14,671 | 15,366 | 17,825 | 14,762 | 14,269 |

| C10 | Processing of sold products | - | - | - | - | - |

| C11 | Use of sold products | 968,174 | 995,115 | 1,183,284 | 670,148 | 642,375 |

| C12 | End of life treatment of sold products | 250,107 | 263,618 | 305,036 | 227,291 | 306,135 |

| C13 | Downstream leased assets | 1,886 | 1,886 | 1,160 | 1,168 | 1,178 |

| C14 | Franchises | - | - | - | - | - |

| C15 | Investments | - | - | - | 402*3 | 350*3 |

| Total of Scopes 1, 2, and 3 Market-based |

2,869,608 | 3,066,176 | 3,551,505*1,2 | 2,541,530*1 | 2,734,618*1 | |

- After using renewable energy electricity certificates from external sources

- The numerical value has been changed because the CO2 emissions from purchased goods and services other than products and parts were added to C1 (Purchased goods and services). However, the additional CO2 emissions in FY2022 (about 2% of the entire Scope 3) are not included in the auditing for ISO 14064.

- Emissions from related companies have been added since FY2023.

Scope

External Assurance

BSI Independent Assurance Statement 2024 [PDF/823KB]

BSI Independent Assurance Statement 2023 [PDF/811KB]

BSI Independent Assurance Statement 2022 [PDF/724KB]

LRQA Independent Assurance Statement 2021 [PDF/141KB]

LR Independent Assurance Statement 2020 [PDF/570KB]

LR Independent Assurance Statement 2015 [PDF/524KB]

Efforts to Reduce CO2 Emissions in Business Sites

Amid rising international interest in achieving a society that balances economic development and environmental conservation, the Brother Group aims to contribute toward a sustainable society by creating and promoting a virtuous cycle of business growth and environmental harmony.

Realization of carbon neutrality

BROTHER INDUSTRIES (U.K.) LTD. and BROTHER INDUSTRIES (SLOVAKIA) s.r.o.

BROTHER INDUSTRIES (U.K.) LTD. and BROTHER INDUSTRIES (SLOVAKIA) s.r.o., which are manufacturing facilities of the Brother Group, attained carbon neutrality and completed PAS 2060:2014* verification. The two facilities received verification in 2021 and 2022, respectively, and continue to receive verification each year. They have achieved carbon neutrality by offsetting remaining emissions with carbon credits in addition to promoting energy-saving activities and fully utilizing renewable energy. The Brother Group will aim to achieve carbon neutrality in all business operations and minimize CO2 emissions from the entire value chain by attaining carbon neutrality in accordance with the standards.

- PAS 2060 (Publicly Available Specification 2060): International standard that certifies the achievement of carbon neutrality

BROTHER INDUSTRIES, LTD. Kariya Factory

In October 2024, Kariya Factory, one of the manufacturing factories of the Machinery business, achieved carbon neutrality in FY2023 and completed the verification of compliance with the ISO 14068-1:2023 standard*. This is the first time that the Brother Group has achieved carbon neutrality in accordance with the ISO 14068-1:2023 standard, and is also the first case in the manufacturing industry in Japan.

To achieve its carbon neutrality, Kariya Factory is working to reduce GHG emissions under a policy to place top priority on both actively introducing renewable energy and improving energy consumption efficiency through energy conservation.

- ISO 14068-1:2023 standard: An international standard (issued on November 30, 2023) that provides principles, requirements, and guidance for achieving and demonstrating carbon neutrality through quantification, reduction, and offsetting carbon footprints in organizations and products

Promotion of energy-saving activities

The Brother Tokyo building was renovated. Specifically, double sashes were introduced to improve the thermal insulation performance, the air-conditioning equipment was replaced by high-efficiency models, and CO2 sensors were introduced to control the ventilation volume. Solar panels were also installed on the rooftop to cover part of the power consumed in the building with renewable energy. As a result, BIL obtained ZEB Ready certification,* which is recommended by the Ministry of the Environment, for the first time.

- ZEB is the abbreviation for "Net Zero Energy Building." ZEB Ready certification is awarded to a building which reduces the annual standard primary energy consumption by 50% or more.

To improve environmental performance while balancing the reduction of CO2 emissions and utility costs, BROTHER INDUSTRIES (SLOVAKIA) s.r.o. (BISK) actively uses natural energy. Since December 2020, BISK has been operating an energy system that combines an air conditioning system using heat from groundwater and a solar power generation system. The air conditioning system that uses groundwater heat utilized a well that was originally within BISK's premises.

TAIWAN BROTHER INDUSTRIES, LTD. and BROTHER TECHNOLOGY (SHENZHEN) LTD. launched activities to visualize energy consumption by area, time, and purpose and to identify waste and make improvements by using data. They also introduced a centralized management system for air conditioning and an abnormality detection system using air flow rate sensors to increase energy efficiency.

In addition, by building and utilizing a smart energy management platform, BROTHER TECHNOLOGY (SHENZHEN) LTD. implemented 10 improvements in FY2024 and continues its energy-saving activities.

Active introduction of renewable energy

In FY2023, solar panels of over 5 MW in total were newly installed at the Hoshizaki Factory (Minami-ku, Nagoya City) and the Research & Development Center (Mizuho-ku, Nagoya City) in Japan as well as at BROTHER INDUSTRIES (PHILIPPINES), INC., BROTHER INDUSTRIES (VIETNAM) LTD., and BROTHER TECHNOLOGY (SHENZHEN) LTD. outside Japan.

In addition, at Minato Warehouse 1 adjacent to the Minato Factory, a combined on-site and off-site PPA* was introduced in FY2023 by using the solar power generation equipment that had been installed in FY2022. Power generated by the solar panels is consumed at Minato Warehouse 1, and the surplus power generated is transmitted to the Brother Museum, which is Brother's exhibition pavilion, and the Brother Head Office building to ensure the efficient use of renewable energy. This is the first pioneering effort in the Chubu area to expand the introduction of renewable energy.

The active introduction of renewable energy was continued in FY2024 with the installation of solar panels at our Group companies, such as Nissei, and signing of a renewable energy power contract through an off-site PPA from Nagano Prefecture.

- Abbreviation for "Power Purchase Agreement". A system whereby a company that owns and manages solar power facilities provides electricity generated by a solar power generation system installed on the premises, roof, or other space provided by the facility owner to the electricity users of the facility for a fee

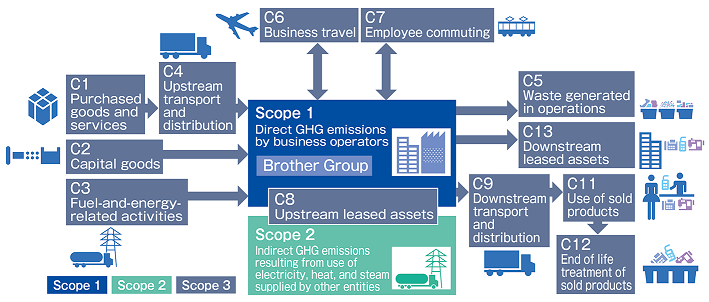

Brother also utilizes electricity generated by solar panels at the Mizuho Factory (Mizuho Ward, Nagoya City) to produce green hydrogen, using a water electrolysis hydrogen production system. The hydrogen produced is delivered to the Brother Museum and used to generate electricity with fuel cells manufactured by Brother and run on hydrogen, so there are no CO2 emissions even during use. In FY2023, this initiative was accredited under the Chubu Region Low-carbon Hydrogen Certification System.* We will continue to promote the reduction of energy-derived CO2 emissions by actively utilizing renewable energy.

- A certification system for three prefectures in the Tokai area to certify hydrogen, whose CO2 emissions are low during its production, transport, and use, as "low-carbon hydrogen" and disseminate information

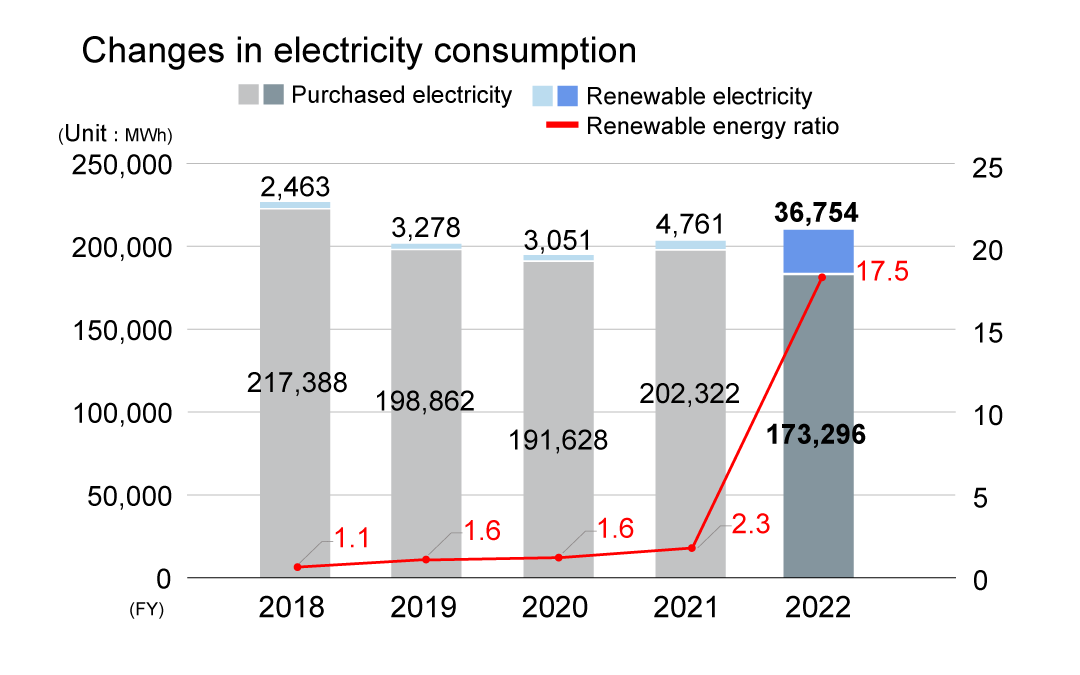

The renewable energy ratio in FY2024 was 28.8% by using renewable electricity (including renewable energy procurement using certificates) in addition to on-site generation. The Brother Group will contribute to protecting the earth by systematically switching electricity used in business operations to renewable energy.

Energy consumption in FY2024

| Total energy consumption | 217,587 MWh |

|---|---|

| Renewable energy consumption | 62,592 MWh |

| : In-house power generation consumption | 13,280 MWh |

| : Amount of renewable energy purchased consumption (including renewable energy procurement using certificates) |

49,312 MWh |

| Renewable energy ratio | 28.77% |

Efforts to Reduce CO2 Emissions in Products

Based on the Brother Group Environmental Action Plan 2024 (2022-2024), the Brother Group has developed measures to reduce CO2 emissions by 150,000 tons* and worked to reduce CO2 emissions from products in the Printing & Solutions Business, Machinery Business, Nissei Business, Personal & Home Business. As a result, it could successfully cut CO2 emissions by 177,000 tons over three years. The Brother Group contributes to the reduction of CO2 emissions through a combination of accumulated small ingenuities and technological innovations at each stage of the product lifecycle.

- Total amount of CO2 emissions reduced by the environmental measures for products newly implemented by FY2024 in comparison with the operations in FY2021. Examples: smaller and lighter products, increased use of recycled materials, reduced standby power consumption, etc.

Reduction in size and weight of a color LED printer (HL-L8240CDW)

The new product has been downsized by 20% compared to the previous model (HL-L3270CDW). Reduction in size and weight has led to reduction in CO2 emissions from raw materials by 12% and those from transport of products by 25%. The power consumption in Deep Sleep* mode has been reduced by 62%.

- As one of the operation modes of devices, it further saves power by restricting more functions compared to Sleep mode, which suspends some of the functions when a device is not operated, etc.

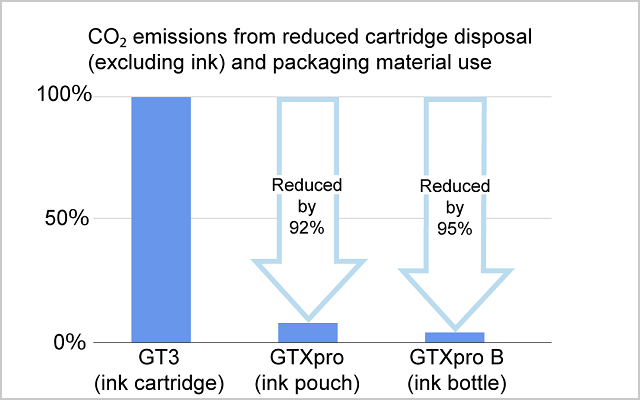

Consumable inks for industrial printers (GTX Pro series)

In the GTX Pro garment printer series, we have been working to reduce the amount of plastic and packaging materials included with consumable ink. By switching from the previous cartridge replacement system to a pouch replacement system and bottle supply system for consumable ink, we have been able to reduce the amount of plastic and packaging materials used for consumables, contributing to a reduction in CO2 emissions compared to the previous system.

|

GT3 (previous cartridge system) (2012) Ink refill by cartridge replacement |

GTXpro (2017) Reduced cartridge waste by using replaceable ink pouches |

GTXpro B (2020) Adopted bottle ink system to reduce waste generated from ink replacement |

|---|---|---|

|

|

|

Realization of bottled ink by installing a white ink agitator

CO2 emissions from cartridge disposal (excluding ink) and packaging material use have been reduced by 92%* for the pouch replacement system and 95%* for the bottle supply system compared to the previous system.

Additionally, the amount of resource used for cartridges and the amount of packaging materials used were also reduced by 82%* for the pouch replacement system and 95%* for the bottle supply system compared to the previous system, leading to a reduction in resource consumption.

- Reduction amount with white ink consumption when printing the test data on 2,500 T-shirts.

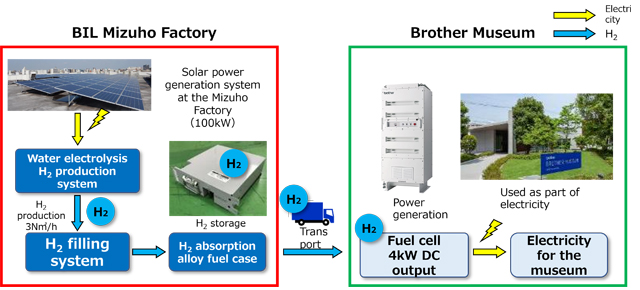

Thinking about the environment from the perspective of electrical energy—toward a future with widespread use of hydrogen

Toward the development of fuel cell systems, Brother has undertaken many years of fuel cell research while pursuing the potential of hydrogen.

There are still many issues in further widening the use of hydrogen. However, the development of this technology was a steady step into the future for Brother.

Collaboration with Suppliers

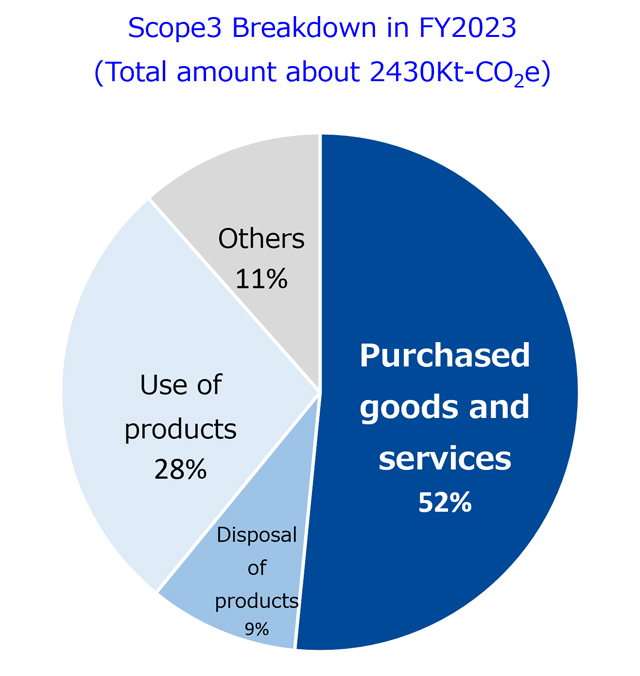

At the Brother Group, purchased products and services account for more than 50% of Scope 3. To achieve our environmental vision, it is essential to reduce CO2 emissions in the phase of procuring products (parts for Brother).

The Brother Group is working with 13 main parts suppliers to reduce CO2 emissions by using renewable energy as electricity during production of parts for Brother. In FY2024, the Group began activities to obtain primary information on CO2 emissions at the stage of producing raw materials for parts and incorporate this information into its Scope 3 calculation system. This has made it possible to reflect the results of our suppliers' CO2 emission reduction activities in Scope 3. As a result, a cumulative reduction of approximately 30,200 tons of CO2 emissions was achieved during the previous medium-term business strategy, CS B2024, covering the period from FY2022 to FY2024.

The scope of this activity will be expanded in stages to involve other parts and raw materials suppliers, with the aim of reducing cumulative CO2 emissions by 120,000 tons by FY2027, the final year of CS B2027.

Contribution to CO2 Reduction for Society as a Whole through Products

The Brother Group has been working to reduce CO2 emissions in all manufacturing processes, including development, procurement, production, sales and logistics, as an activity that is directly linked to our business. In order to curb climate change (global warming) and achieve a decarbonized society, it is also necessary to work to reduce CO2 emissions for society as a whole. For example, reducing the amount of electricity consumed by our customers (electricity consumption) through the improvement of energy-saving performance of Brother products and services, will reduce CO2 emissions when customers use our products, which will lead to a CO2 reduction for society as a whole. In addition, saving resources by increasing the capacity of consumables will lead to a CO2 reduction when procuring raw materials and disposing of consumables. To measure and increase our contribution, we define and visualize avoided CO2 emissions as the CO2 reduced for society as a whole.

We will continue to promote the reduction of CO2 emissions from the Brother Group by providing Brother products and services that lead to a CO2 reduction from customers which will contribute to CO2 reduction for society as a whole.

Performance of Avoided CO2 Emissions

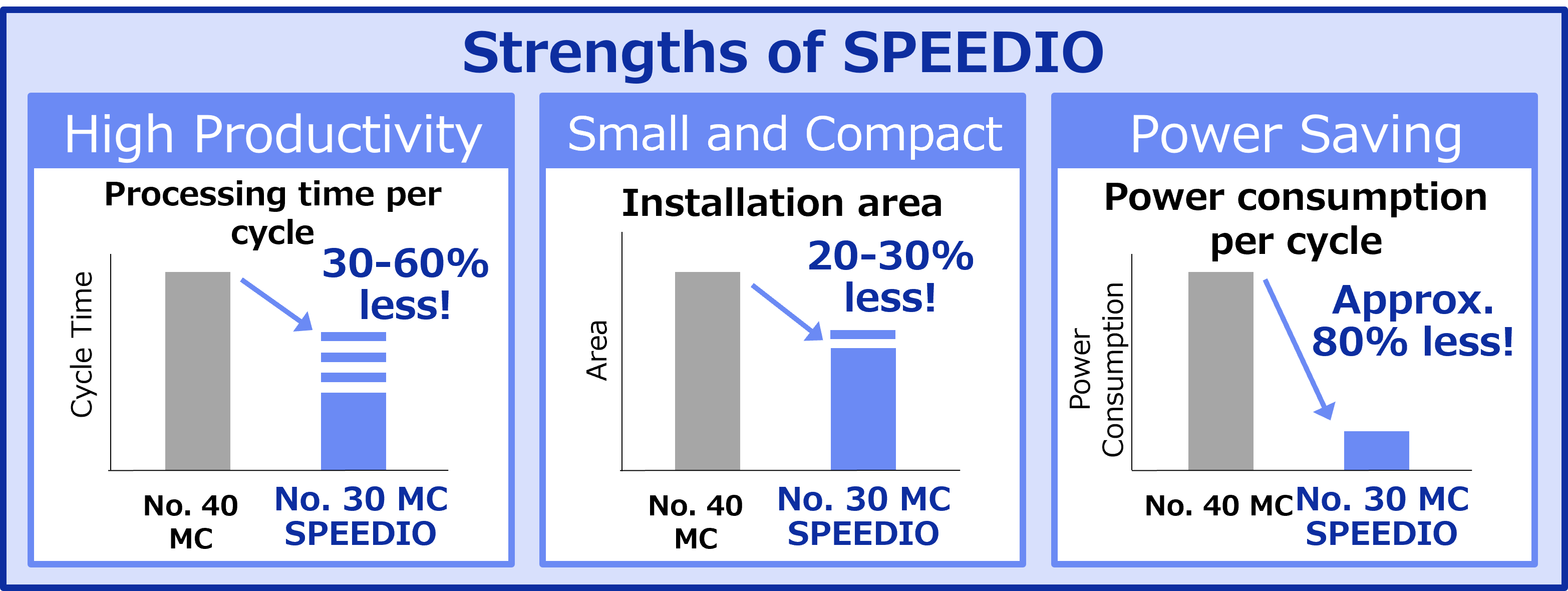

The Brother Group is working to contribute to the reduction of CO2 emissions by improving the energy-saving performance of all products, including printing products, machine tools, industrial sewing machines, home sewing machines, and new business products, and by reducing consumption of resources, including packing materials. As an example of calculation, a graph of avoided CO2 emissions for the SPEEDIO machine tools through the improvement of energy-saving performance is shown below.

The SPEEDIO models perform optimization control to fully demonstrate machine performance based on NC control, which was developed in-house. We also focus on the concept of eliminating all waste, such as reducing consumption of electricity and air when the operation of machines is stopped and enabling efficient placement even in limited spaces through compact designs. We contribute to reducing CO2 emissions at customers' sites by realizing high production efficiency and energy-saving performance.

Machine Tools to Improve Productivity and Reduce CO2 Emissions - Brother's Machining Centers Contribute to a Carbon-Free Society

Method of Calculation of Avoided CO2 Emissions (based on internal research)

![Avoided CO2 emissions for machine tools [Total from 2020 to 2024] (graph)](/-/media/global/sustainability/img/eco/co2/co2-mt-en.ashx)

Compared Brother's product (SPEEDIO No. 30 spindle machine) to competitor's products (No. 30 and No. 40 spindle machines), calculated the contribution to avoided CO2 emissions in the product use stage that could be achieved through improving energy-saving performance and other means.

- Calculation formula (competitor product CO2 emissions - Brother product CO2 emissions) x number of products sold (estimated 10 years of product use)

- CO2 emissions from competitor products are calculated based on data obtained by running general No. 30 and No. 40 spindle machines based on Brother's scenarios with a processing program developed by Brother (No. 30 and No. 40 spindle machines refers to the size of the tool attachment area and are machine tool industry terms that represent product categories)

- Avoided emissions are based on Brother's original scenarios and differs from the actual reduction.

- Calculation details are supervised by a third-party expert based on the Ministry of Economy, Trade and Industry's "Guidelines for Quantifying GHG emission reductions of goods or services through Global Value Chain" (March 2018).

In addition, the avoided CO2 emissions in FY2024 was about 20,000 tons, which was achieved by increasing the capacity of consumables to reduce the number used and packaging materials for the aforementioned color LED printers and garment printers.

External Award (Energy Conservation Grand Prize)

As a result of improving energy efficiency and reducing CO2 emissions of various products and services, the Brother Group has received external awards, including the Energy Conservation Grand Prize sponsored by the Energy Conservation Center, Japan.

<Award History>

| Award Name | Award-winning product/News release |

|---|---|

| FY2024 Machine tool "SPEEDIO" Energy Conservation Grand Prize, Agency for Natural Resources and Energy Commissioner's Award |

|

| FY2023 Personal No-Exhaust-Heat & CFC-Free Spot Cooler "PD-3100" Energy Conservation Grand Prize, Agency for Natural Resources and Energy Commissioner's Award |

|

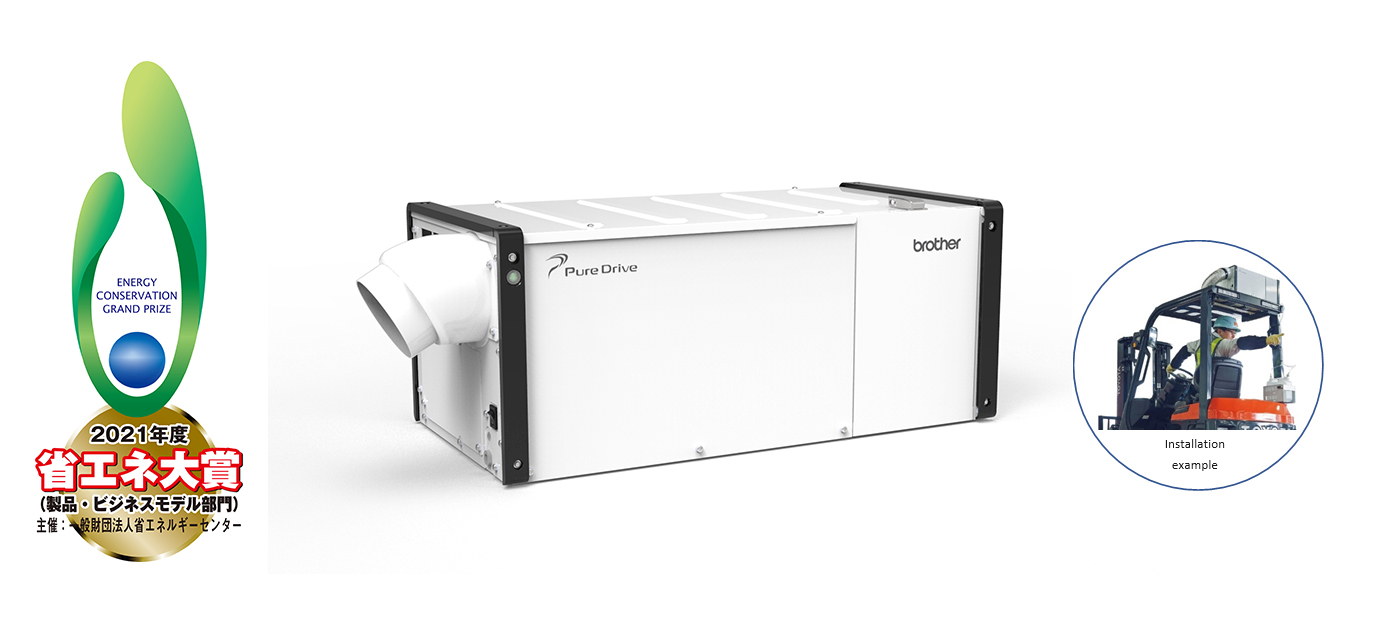

| FY2021 CFC-Free Spot Cooler for Forklifts "Pure Drive-FL" Energy Conservation Grand Prize, The Energy Conservation Center, Japan Chairman's Award |

|

<Overview of Award-winning Products>

FY2024 "SPEEDIO": Achieved high productivity, compactness, and energy efficiency, contributing to reducing customers' CO2 emissions.

Machine tool SPEEDIO is a #30 spindle machining center that combines expanded machining area and compactness with excellent energy efficiency. It contributes to energy-saving and CO2 reduction for customers through its warm-up-free function, which reduces power consumption by approximately 10%, as well as its chip shower control according to chip volume. Furthermore, by expanding the machining area of the Y/Z axes while maintaining the external dimensions, it is now possible to machine some parts that were previously machined using medium-size machine tools of #40 to #50 machines. In recognition of these high environmental performance features, SPEEDIO received the Energy Conservation Grand Prize and Agency for Natural Resources and Energy Commissioner's Award in FY2024. SPEEDIO also received the Aichi Environmental Award sponsored by Aichi Prefecture in the same year.

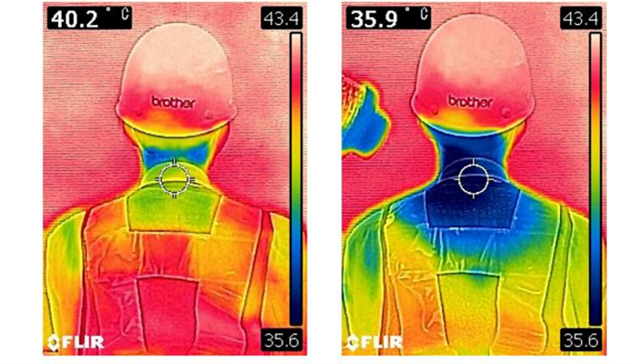

FY2023 "PD-3100": Downsizing Pure Drive-FL and improving its energy efficiency enabled heat protection even in towing vehicles and trucks.

PD-3100, a personal no-exhaust-heat and CFC-free spot cooler, has a smaller body size compared with Pure Drive-FL, a forklift spot cooler. Moreover, by incorporating the water tank into the unit, it is now possible to install it in a more space-efficient manner. Its compact product design allows it to be installed behind the seat of a forklift, enabling comfortable work while receiving cool air even when working inside a container with height restrictions. In addition to forklifts, the system can also be installed on towing vehicles used to transport goods in factories and logistics warehouses, contributing to the creation of a safe, comfortable, and easy-to-work environment for many more workers.

Recognized as an excellent product that achieves both energy conservation and improved working environment, PD-3100 won the Energy Conservation Grand Prize and Agency for Natural Resources and Energy Commissioner's Award in FY2023.

FY2021 "PureDrive-FL": Heat protection measure realized with an energy-efficient spot cooler for forklifts

As rising temperatures due to climate change are inevitable, the Brother Group has commercialized PureDrive-FL, a CFC-free spot cooler for forklifts that pursues energy efficiency and comfort for forklift operators as one of its "adaptation" measures to minimize the impact of climate change. This product uses a unique evaporative cooling system that does not use fluorocarbon refrigerants, thereby reducing environmental impact and achieving both heat countermeasures and CO2 emission reduction at the same time. Compared to spot coolers that use air conditioning systems, power consumption is reduced to about one-third, and by enabling individual air conditioning in logistics areas, energy consumption in conventional logistics areas has been reduced by 92%. In recognition of these achievements, PureDrive-FL received the Energy Conservation Grand Prize and the Energy Conservation Center, Japan Chairman's Award in FY2021.

In addition, in November 2024, the "PureDrive-FL" was presented as a leading example of CO2 emissions reduction efforts by a Japanese company at the CO2 Reduction Contribution Evaluation Session held during EcoBalance 2024, an international conference organized by experts from industry, government, and academia.

2025 CDP Questionnaire

CDP (formerly the Carbon Disclosure Project) is an international non-profit environmental organization founded in 2000, whose disclosure system sets the global standard for environmental reporting in the global economy.

CDP's environmental data is used by financial markets, policy initiatives, and various other stakeholders.

Brother Industries, Ltd. (BIL) has been participating in CDP Climate Change since 2011 and in CDP Water Security since 2015, and has been responding to the questionnaires.

- In 2024, questions regarding Climate change, Forests, Water security, Plastics, and Biodiversity were integrated into the CDP Questionnaire.