- Value Creation Activities

- "Value" Chain Starting with Customers

- Product Planning, Research and Development

- Development Design, Production Engineering

- Manufacturing, Distribution, Sales and Service

- Intellectual Property

Brother Maximizes Synergies through Joint Development with Domino

Brother incorporates its own print head with proprietary inkjet technology into the Domino brand products

The N730i digital label printer is a product jointly developed by Brother Industries, Ltd. ("BIL") and its subsidiary, Domino Printing Sciences, plc ("Domino Printing"). The N730i is equipped with BIL's own BITSTAR™ print head, which utilizes the inkjet technology that BIL has cultivated over the years. In addition to a high resolution of 1200 dpi, the combination of the industry's smallest ink droplet sizes improves print quality and achieves a print speed of 70 m/min, including white printing. Furthermore, as the main unit, print head, and ink are all developed by the Brother Group, Brother also focuses on providing prompt maintenance service from the customer's point of view.

Since BIL made Domino Printing its wholly-owned subsidiary in 2015, it has been striving to maximize synergies through group-wide business operations. The joint development of products between BIL and Domino Printing is a synergy that Brother has been aiming for since the acquisition of Domino Printing, and their knowledge was applied to N730i. Brother Group will continue to work as one to achieve further development in the industrial printing area.

Brother Develops Industrial Thermal Printer to Expand Sales in Asian Markets

Brother realizes high-quality printing at any speed by utilizing its printer technologies

Thermal transfer* (thermal) printers are typically installed in food production lines because they do not use liquid ink for printing, and therefore, there is no risk of ink migration. Brother has developed the Vx150i industrial thermal printer, which is used to print expiration dates and barcodes on plastic film packaging materials, by utilizing the thermal transfer technology used in its P-touch label makers. With this product, Brother aims to expand sales in Asia, which is the most important market for Domino Printing's thermal printer business.

By enhancing product quality and reliability, Vx150i has achieved stable high-speed continuous printing even in the harsh environment of Asia, with its high temperature, high humidity, and dust, while significantly reducing the frequency of parts replacement compared to previous models. The Vx150i basic model also features the cassette loading system for ink ribbons that was previously available only on higher-end models. This system makes it easier to replace ink ribbons, reducing the workload when replacing ink ribbons and contributing to improved productivity of customers. Furthermore, in addition to the low cost achieved by combining resin and metal in its design, the use of more resin to reduce product weight also reduces CO2 emissions during transportation. Vx150i has been highly rated in the Asian market as a basic model that offers productivity and reliability comparable to higher-end models.

The Brother Group will remain committed to advancing its technological capabilities to provide the best products for customers.

- A technology that creates an image by transferring heat-sensitive ink from a ribbon onto a substance such as paper

Brother Ensures Stable Procurement of Cost-Competitive Parts

Brother enhances collaboration with its suppliers through parts exhibitions at manufacturing facilities

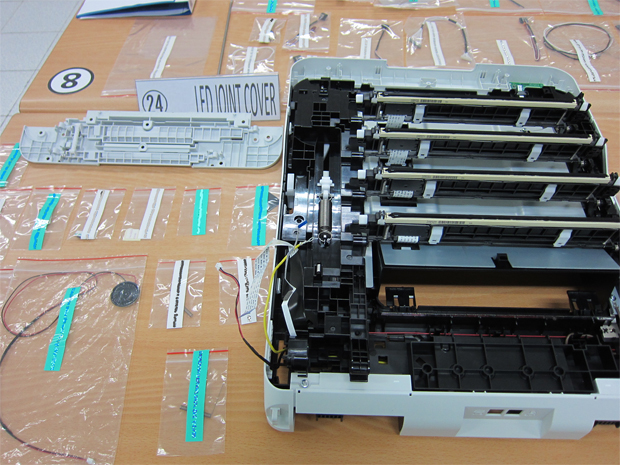

The Centralized Procurement Dept. of the Quality, Production & Engineering Center at Brother Industries, Ltd. has been strengthening ties with Brother's suppliers through parts exhibitions held at Brother's main facilities outside Japan to better procure parts.

The parts exhibition in FY2024 at manufacturing facilities of Printing & Solutions business in Vietnam and the Philippines had approximately 600 visitors from more than 240 partner companies and provided a productive opportunity to exchange various opinions.

In such parts exhibitions, the Centralized Procurement Dept. provides information about precautions in product assembly, key points in quality management, packaging forms, and so forth to participating suppliers while working together with the procurement, production, and quality management departments in Brother's manufacturing facilities. Subsequently, the departments solicit those suppliers' ideas and suggestions on cost reduction and the possibility of local procurement. The suppliers, meanwhile, aim to expand their business by considering how to contribute to Brother's manufacturing with their production technologies.

One of the participating suppliers commented that participation in the parts exhibitions enables him to get a deeper understanding of even the parts that his company has never supplied, and thus gives him a good opportunity to identify his company's strengths and weaknesses and reflect them in quality and cost improvement efforts for further business development.

The Brother Group will continuously strive to build strong trusting relationships with its business partners and grow and develop together to ensure stable procurement of high-quality and cost-competitive parts in dramatically changing business environments.

Brother Strengthens Its Production System through Digitalization

Brother transforms customer needs into products and solutions with a digital production support system that ensures consistent quality

BIL’s Kariya Factory has introduced and is operating the digital production support system “B-PACS” (Brother Point Analytical Control Supporting) to further advance the production of machine tools.

Machine tools, often referred to as “mother machines” because they cut materials to create various parts, play a vital role in supporting customers’ high-precision parts machining and manufacturing. As such, it is particularly important to deliver machines tailored to customer specifications on schedule and with high quality. To address this challenge, the Kariya Factory, which produces machine tools, has introduced B-PACS to achieve higher quality and more stable production. By using tablet devices to digitize production processes, the system enables real-time management of work progress and man-hours. This has made it possible to move away from managing production processes with over 100 sheets of paper, allowing work process and quality data to be input and checked instantly. In addition, data such as screw-tightening records are automatically captured and transferred, which significantly reduces operational errors, enables early detection of defects, and supports quick resolution. The system has also been rolled out to Brother Machinery Xian Co., Ltd., our manufacturing facility in China, contributing to the strengthening of our global production structure. Furthermore, because operators can check work procedures instantly on tablets while working, the time required to learn tasks has been shortened, facilitating the early development of new operators. In terms of talent development, we are also promoting production enhancement through education, such as providing opportunities to improve skills and learn the essence of manufacturing at the Takumi Dojo. Through these efforts, we deliver machines, on time and with high quality, that meet customer specifications.

BIL will continue to evolve its production system to quickly provide superior value to customers.