- Creating Eco-Conscious Products

- Environmental Compliance of Products

- Disclosure of Environmental Attributes

- Collaboration with Suppliers

- Acquisition of Environmental Certifications

- Collection, Remanufacturing and Recycling Efforts in Various Countries

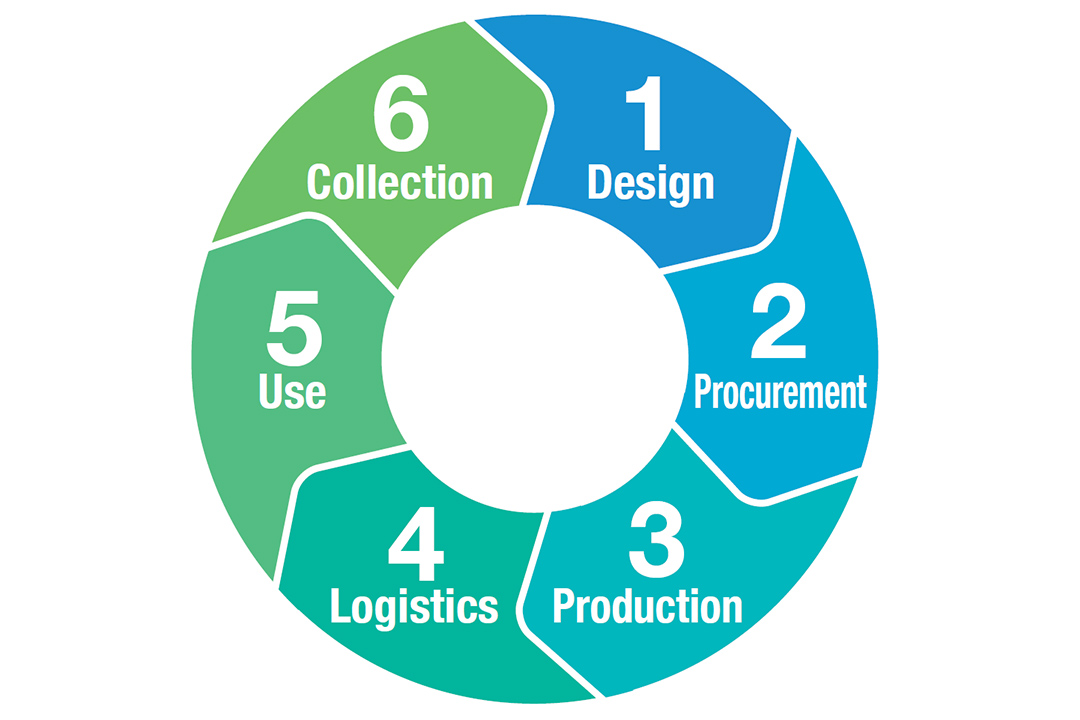

Setting Ever Higher Targets for Reducing Environmental Impact at Each Stage

The Brother Group is committed to reducing environmental impact at all stages of the life cycle of its products. This is the guiding principle of the group's manufacturing activities.

Since each of the stages are closely interlinked in terms of environmental impact, continuous efforts are necessary to make incremental improvements and to achieve technological innovation at all stages, without being selective to any particular stage. The Brother Group aims to make such efforts throughout its operations in order to continuously deliver eco- conscious products to customers.

1. Development and Design

Basic policy

Brother products are developed and designed to:

- comply with laws and regulations of the various countries and regions where sold;

- be compact and lightweight to conserve resources;

- achieve the top levels of energy conservation performance in the industry;

- meet hazardous chemical substance management standards, as specified in the Brother Group Green Procurement Standards and environmental labels;

- be easily recycled or reused at the end of life; and

- meet emission standards (for chemical substances, noise, etc.);

- meet the set CO2 emissions reduction targets for the products.

When trying to develop a product that will be eco-conscious throughout its entire life cycle, it is essential to apply these principles at the development and design stage.

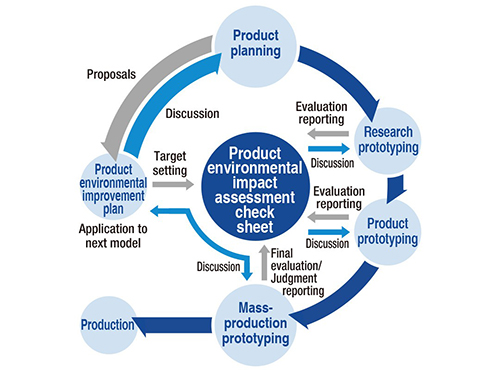

For the key criteria listed in the product environmental impact assessments, target values are set at the initial stage of development and design.

Measures

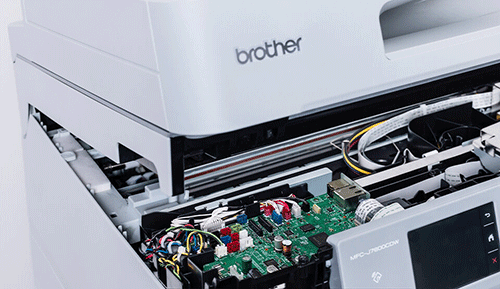

Brother Industries, Ltd. (BIL) conducts product environmental impact assessments at key stages of development and ensures eco-conscious design by addressing the product life cycle from material procurement, production, packaging, products use and through to the collection and recycling at the end of life.

Also, BIL actively acquires environmental labels in respective countries. For European customers in particular, BIL discloses product information in accordance with the Eco Declaration (ECMA-370).

Product environmental impact assessments and Life Cycle Assessment (LCA)

BIL conducts product environmental impact assessments in order to evaluate the impact that products have on the environment through the product life cycle from material procurement, production, packaging, products use, up to collection and recycling at the end of life. For key criteria under the assessment items, reduction of environmental impact must be achieved at the product development stage.

Key Criteria for product environmental impact assessment

- Disassembly/dismantling of products

- Material labeling of resin parts

- Reusability/recyclability of parts

- Hazards and toxicity during product production/use, hazards and toxicity in packaging materials

- Compliance with related laws and regulations

- CO2 emissions reduction measures for products

We conduct an LCA that quantitatively provides numerical data for "the degree of impact on the environment" at each stage of a product's life cycle. Environmental load characteristics and improvement points are identified and the improvement effect is confirmed for each product. Evaluation results are released on the website managed and operated by the Sustainable Management Promotion Organization (SuMPO) under the SuMPO EPD (Environmental Product Declaration).

- SuMPO EPD

(Link to the "SuMPO EPD" website.)

2. Procurement

Basic policy

We check parts and materials that are used to make products, to ensure:

- they do not contain hazardous materials ; and

- they are made via an eco-friendly process.

In this way, we give priority to purchasing parts and materials. In June 2024, the Brother Group revised its Environmental Guidelines for Suppliers, and it has been working together with suppliers that manufacture parts for Brother products to minimize their greenhouse gas emissions.

Measures

Brother works with suppliers and uses the IT-based Brother Group Green Procurement Management System to manage data on the chemical substances contained in its products and promote the use of alternative parts and materials. This is regularly updated in response to the candidate list substances of very high concern defined within the REACH Regulation.

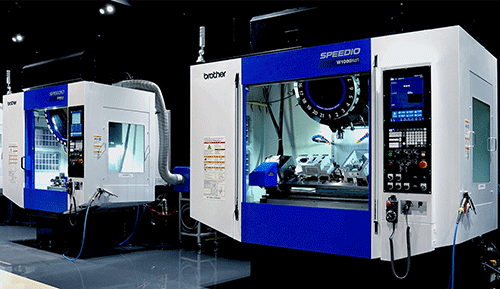

3. Production

Basic policy

The Brother Group's manufacturing facilities manufacture products with due consideration given to:

- ensuring efficient use of materials, energy, and water resources, etc.;

- reducing pollutants released into the atmosphere and wastewater;

- preventing the generation of waste; and

- recycling waste generated.

Measures

- Electrical power consumption and CO2 emissions are reduced by ensuring all manufacturing facilities efficiently run equipment.

- Products with consideration for resource circulation and waste are manufactured, including the conduct of Zero Waste Emission Activities to eliminate landfill waste

4. Packaging and Logistics

Basic policy

Brother is committed to:

- reducing product packaging and waste where possible; and

- reducing CO2 emissions in logistics and transportation.

Measures

- We are combining product categories when arranging shipments to maximize loads.

- We continue to review distribution routes.

- We are applying smaller packaging and elimination of styrofoam. In May 2025, we have won the WorldStar Award at the WorldStar Global Packaging Awards 2025, hosted by the World Packaging Organisation (WPO).

5. Use

Basic policy

Brother takes the following into consideration regarding customer use of our products:

- they do not consume excessive energy; and

- our products can be used safely, conveniently and comfortably.

We also endeavor to disclose overall environmental information about products.

Furthermore, by obtaining the environmental label certification, we indicate that the product complies with the environmental label standards for power consumption during product use, chemical substances, noise, and other emissions.

Measures

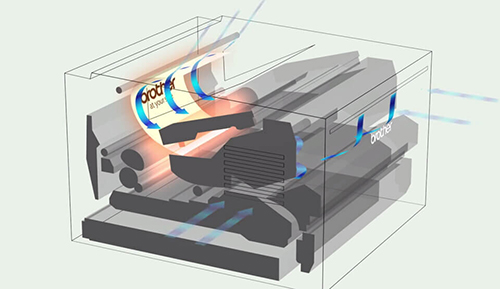

We are strengthening development of eco-conscious products focusing on energy conservation.

6. Collection and Recycling

Basic policy

Brother takes the following into consideration regarding the end of customer use of a product:

- collect and recycle products and consumables at end of life; and

- design products so that they can be easily recycled.

Measures

- Ink cartridges consumed in Japan. The Ink Cartridge Return Project is under way in collaboration with printing product manufacturers.

- For toner cartridges, drum units, and label writer tape cassettes consumed in Japan, Brother's own collection and recycling system is in place.

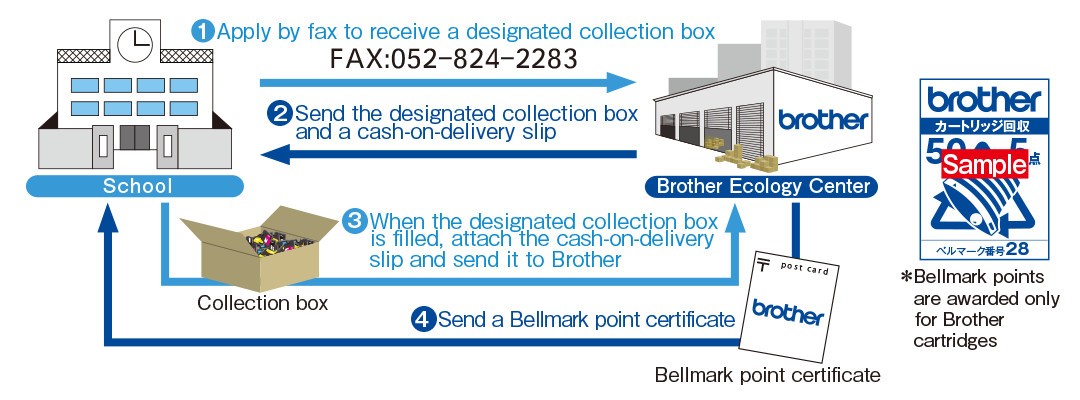

- Participating in the Bellmark campaign through collection of used cartridges, and carrying out environmental conservation activities and education support.

- For toner and ink cartridges consumed outside Japan, collection and recycling systems are in place in more than 40 countries and regions. In Europe in particular, we are not only collecting and recycling*1 cartridges, but also remanufacturing*2 them.

- Recycling: Crushing used cartridges and reusing them as raw materials or energy sources

- Remanufacturing: Cleaning and inspecting used cartridges to create cartridges of the same quality as new cartridges

- In Europe, products are collected and recycled in accordance with the WEEE Directive. In New Zealand, products are collected and recycled on a voluntary basis. Regarding corporate customers in Japan, used Brother products (fax machines, printers, and All-in-Ones) are collected and recycled in collaboration with business partners.

[Brother's activities] Conducting eco activities through the Bellmark campaign (Japan)

Brother Sales, Ltd. joined the Bellmark campaign in order to (i) actively participate in social contribution activities via support for education and (ii) improve the collection rate of used cartridges and promote recycling.

Examples of products in the Bellmark campaign