We help our customers enhance their manufacturing competitiveness through our products, such as industrial sewing machines that are easy to use, energy-efficient, and enable high-quality sewing, as well as machine tools that are ideal for machining parts for automobiles, general machinery, and the like.

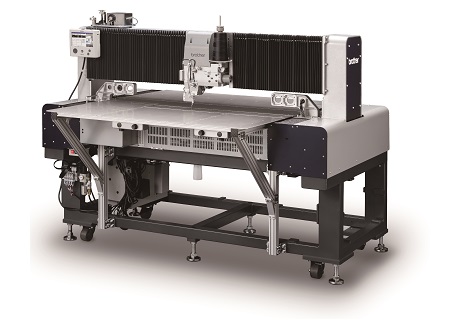

Achieving Improved Productivity Through Strong Energy-saving Performance and High Processing Capabilities

Industrial equipment

Brother’s industrial equipment was developed through our manufacturing of machine tools needed to make key parts of sewing machines in-house. Offering high productivity and energy-saving performance while being compact, our equipment is highly evaluated in the processing of parts needed by the automobile, general machinery, and other industries. In addition to expanding our product lineup, we are also developing peripheral equipment, for example, optional devices that can automatically transport and supply processed parts, to propose optimal solutions in a wide range of fields, including electric vehicles, other automobiles, and medical devices.

Providing Excellent Productivity and Consistent Sewing Quality

Industrial Sewing Machines

Brother has been continuously leading the industrial sewing machine industry in fabric (cotton, linen, and so forth) sewing. Our products allow high-speed sewing and beautiful stitches, being well received by customers who produce airbags, shoes, and so forth. We will continue to provide high-value-added products and propose automation solutions.