02UNIQUE TECHNOLOGY AND EXPANSION

ENERGY

SAVING

Machine Tools with Outstanding Environmental Performance that Contribute to Carbon Neutrality

SAVING

contents

-

“Power Regeneration”: The Key to Environment Performance

-

Uses a Highly Efficient IPM Motor

-

Thoroughly Eliminate Wasteful Operations and Time

Brother’s machining center (machine tool) is used in a variety of manufacturing sites, including in the manufacture of automotive components, information devices, and precision machined parts related to aircraft. It is also important to reduce power consumption at sites where hundreds of machines are installed. Brother’s SPEEDIO reduces the power consumption of one cycle by about 80%* compared to a general machining center. Low power consumption helps our customers, and contributes to CO2 reduction efforts at manufacturing sites.

In comparison with a machine tool with a No. 40 spindle specified by our company, when operating with the machining program prepared by our company. Actual power consumption varies depending on the type of processing and tools used.

“Power Regeneration”: The Key to Environment Performance

The key to environmental performance is “power regeneration,” which is applied in a wide range of fields such as electric vehicles and trains. The spindle is the key to processing with a machining center. During processing, the spindle repeatedly accelerates and decelerates rotation many times, but SPEEDIO reuses the energy generated during deceleration as electric power through “power regeneration technology.”

Uses a Highly Efficient IPM Motor

An IPM motor is used for the spindle motor. Compared to a normal induction motor, it efficiently and instantly starts up. Because it has a high-efficiency motor with high torque in the medium to high speed rotation range, it realizes both work efficiency and energy saving. In addition, low power consumption is achieved by energy-saving equipment such as energy-saving pumps, LED interior lights, and reduction of air consumption.

Thoroughly Eliminate Wasteful Operations and Time

Brother has also developed an NC device (a device that numerically controls operation) in-house. This device thoroughly eliminates wasteful operations and wasteful time, which shortens work time to contribute to energy savings for the entire manufacturing site. In addition, a variety of functions such as auto coolant off, auto machine lights off, and auto power-off are installed to ensure power saving.

See more

-

01

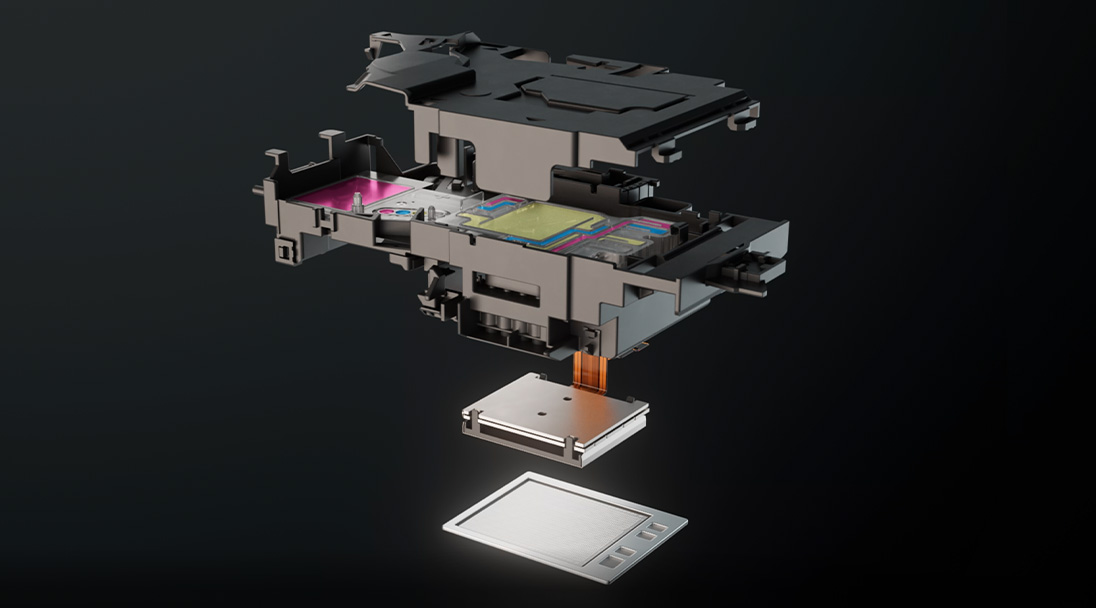

- COMPACTNESS & USABILITY

- Technology Focused on the Compactness and Usability of Brother Printers

-

03

- TECH FOR GARMENTS

- Accuracy and Speed: Inkjet Printing Technology for Garment Printers

-

04

- MAXIDRIVE BENEFIT

- New Inkjet Printing Technology to Deliver Speed and Durability

-

05

- ACCURATE & FAST SEWING

- Accurate control technologies achieve diverse sewing applications and high productivity for industrial sewing machines

-

06

- ROBUST LABELS

- Powerful technologies that meet customers’ label needs