05UNIQUE TECHNOLOGY AND EXPANSION

ACCURATE

FAST SEWING

ACCURATE & FAST SEWING

Accurate control technologies achieve diverse sewing applications and high productivity for industrial sewing machines

FAST SEWING

contents

-

Unique bridge type mechanism enables large sewing area

-

Precise drive control synchronized to fast sewing speed (40 sti/sec or more)

-

Customizable to various sewing environments

Brother’s NEXIO BAS series of industrial sewing machines have a reputation for high-speed, high-accuracy sewing. Bridge type programmable electronic sewing machines in particular, which employ a unique bridge type mechanism, enable a broad range of customers to achieve high productivity. Through fast and accurate control technologies developed by Brother, they enable automatic sewing of various items from apparel and bags to automobile seats and airbags.

Unique bridge type mechanism enables large sewing area

Brother’s programmable electronic sewing machines achieve high-speed, high-accuracy sewing. Employing the company’s unique bridge type mechanism, they enable automatic sewing on flat surfaces, with accurate control of plate movement in the vertical direction, machine head movement in the horizontal direction, and needle movement. With a large sewing area as well, these machines also contribute to improved productivity for various sewing applications, from apparel and leather products to airbags and other industrial products.

Precise drive control synchronized to fast sewing speed (40 sti/sec or more)

The selling points of Brother’s BAS series of sewing machines are high speed and high accuracy. With high speed needle operation of 40 stitches or more per second*, even slight mis-timing of the plate and machine head movement can result in immediate needle breakages. Brother has achieved fast and accurate control of the plate, machine head, and needle to produce world-leading beautiful sewn products.

* Maximum sewing speed of 2,500–2,700 sti/min (depending on the model)

Customizable to various sewing environments

Brother’s bridge type programmable electronic sewing machines provide a large sewing area that supports multiple item setups simultaneously. The machine head can also be raised to enable contactless sewing of thick materials as well. In combination with cutters and other processes, the range of sewing applications can be extended even further. These machines can be customized to support the diverse production environments of customers.

See more

-

01

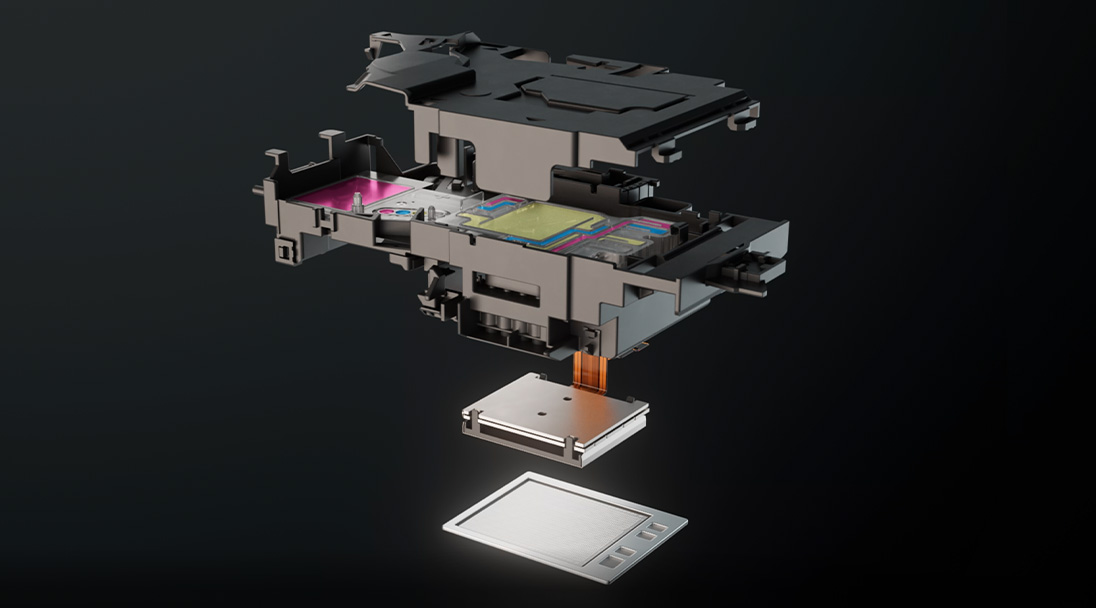

- COMPACTNESS & USABILITY

- Technology Focused on the Compactness and Usability of Brother Printers

-

02

- ENERGY SAVING

- Machine Tools with Outstanding Environmental Performance that Contribute to Carbon Neutrality

-

03

- TECH FOR GARMENTS

- Accuracy and Speed: Inkjet Printing Technology for Garment Printers

-

04

- MAXIDRIVE BENEFIT

- New Inkjet Printing Technology to Deliver Speed and Durability

-

06

- ROBUST LABELS

- Powerful technologies that meet customers’ label needs