06UNIQUE TECHNOLOGY AND EXPANSION

ROBUST

LABELS

ROBUST LABELS

Powerful technologies that meet customers’ label needs

LABELS

contents

-

Choice of Brother labels depending on the application

-

Special abrasion-resistant labels developed for applications requiring even greater durability

-

Control labels for automated transportation robots

Brother Label Printers offer a range of models and labels depending on the application. Labels on factory floors are subject to a particularly high degree of abrasion as forklifts and automated transportation robots travel back and forth. Conventional labels must be frequently replaced as a result, so Brother developed a range of robust labels with a high degree of abrasion resistance. With excellent wear resistance of the print surface, these labels have reduced the burden on customers.

Choice of Brother labels depending on the application

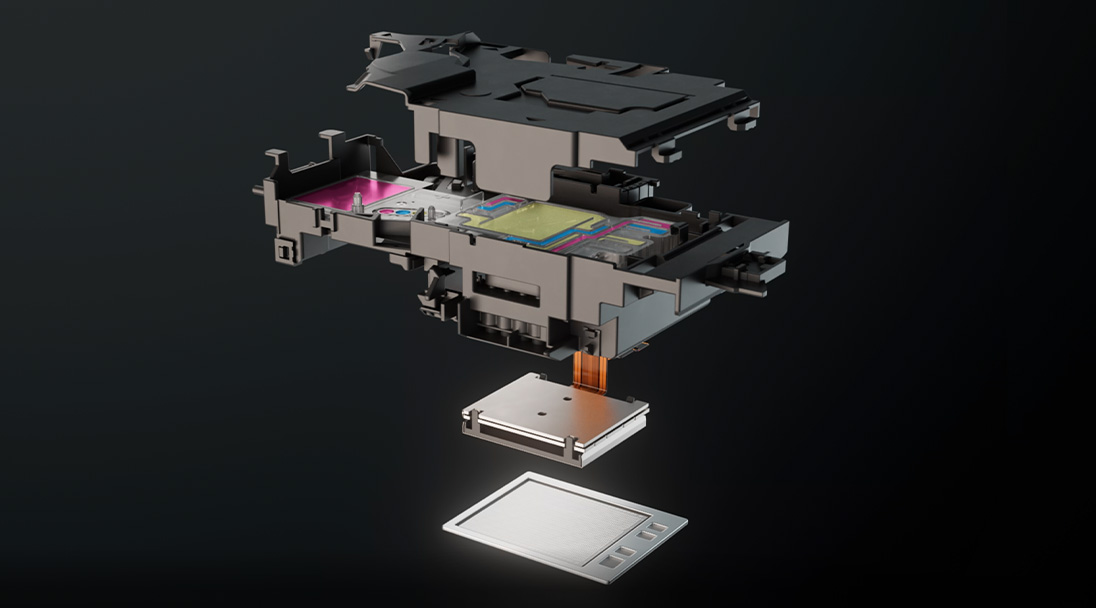

Brother Label Printer labels are generally one of two types; direct thermal labels or thermal transfer labels. Direct thermal labels are economical because they do not require ink, and they are used extensively for applications like product labels and food labels. Thermal transfer labels, on the other hand, print via an ink transfer method that takes longer but produces longer-lasting labels. Thermal transfer labels also come in a laminated type, which is used for applications requiring heat, water, and chemical resistance, such as labels for nameplates or for medical uses.

Special abrasion-resistant labels developed for applications requiring even greater durability

In situations with particularly high rates of wear due to foot and vehicle traffic, such as factory floors, conventional thermal transfer labels sometimes become difficult to read over time as the lettering wears away. For this reason, Brother applied its unique technologies to develop special abrasion-resistant ribbons and dedicated vinyl labels for applications that require even greater durability. As a result, it succeeded in developing labels with print surfaces that have greater wear resistance and adhesion.

Control labels for automated transportation robots

Abrasion-resistant labels, with increased wear resistance enabled by Brother’s unique technologies, have longer-lasting print surfaces that are suitable for warning labels affixed to floors with high traffic levels, including forklifts. They can be used with confidence as control labels for automated transportation robots without requiring protective tape. The dedicated vinyl labels, with a softer material and greater adhesion, exhibit less peeling and are easier to replace even on asphalt, non-slip surfaces, or other rough surfaces.

See more

-

01

- COMPACTNESS & USABILITY

- Technology Focused on the Compactness and Usability of Brother Printers

-

02

- ENERGY SAVING

- Machine Tools with Outstanding Environmental Performance that Contribute to Carbon Neutrality

-

03

- TECH FOR GARMENTS

- Accuracy and Speed: Inkjet Printing Technology for Garment Printers

-

04

- MAXIDRIVE BENEFIT

- New Inkjet Printing Technology to Deliver Speed and Durability

-

05

- ACCURATE & FAST SEWING

- Accurate control technologies achieve diverse sewing applications and high productivity for industrial sewing machines